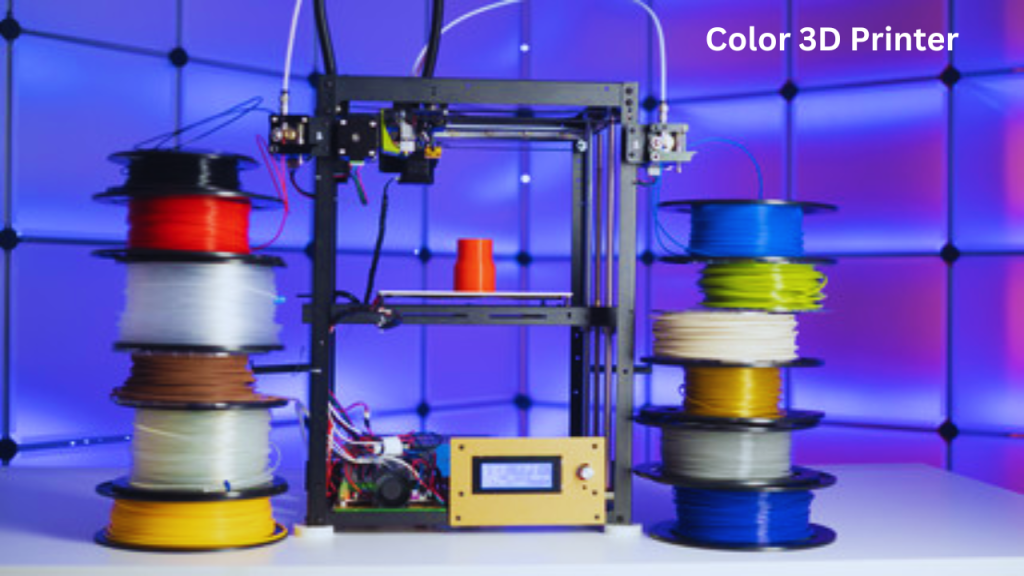

Are you in the market for a color 3D printer but feeling overwhelmed by all the options? Look no further – this guide is here to help! In just a few minutes of reading, you’ll have a clear understanding of the different types of color 3D printing technologies and how they can meet your specific needs.

Whether you’re looking for bright colors, photo-realistic effects, or fine details, we’ve got you covered. So let’s dive in and find the perfect color 3D printer for you!

Direct Color and Color Mixing 3D Printing

If you’re looking for a 3D printer that can achieve vibrant colors and good details, direct color printing with FDM technology might be the right choice for you. Direct color 3D printing involves using colored filaments in an FDM printer. With this method, you can print in a single color or even two colors if your printer has a dual extruder. Some printers also allow for multiple colors and gradients through color mixing.

Direct color 3D printers are affordable and easy to use, making them accessible to a wide range of users. However, it’s important to note that they may not achieve specific color tones and there may be visible layer lines on the printed objects.

The number of extruders in an FDM printer can affect the chance of print errors. While single extruder printers require stopping the printing process to switch out filaments for different colors, printers with multiple extruders can print with more than two colors simultaneously.

Overall, direct color 3D printing is suitable for applications that do not require photo-realistic effects but still want vibrant colors and good details.

Color Matching 3D Printing

Color matching allows you to create custom 3D printed parts in almost any desired color. With color matching, you have the ability to truly personalize your prints and bring your ideas to life. Here are four reasons why color matching is a great option for your 3D printing needs:

Endless Color Options

Color matching opens up a world of possibilities when it comes to choosing colors for your prints. Whether you want vibrant hues or subtle shades, the choice is yours. You can match specific Pantone colors or create unique blends that perfectly suit your project.

Customization

Color matching gives you the freedom to tailor your prints to your exact requirements. Whether you’re creating prototypes, models, or functional parts, being able to choose the right color can enhance their appearance and make them more visually appealing.

Realism

When it comes to creating realistic objects, color plays a crucial role. With color matching, you can achieve lifelike finishes that closely resemble real-world materials and textures. This is particularly useful for applications such as architecture models or product design.

Branding and Personalization

If you’re looking to incorporate branding elements into your 3D printed parts or add a personal touch, color matching is an ideal solution. You can match corporate colors or choose shades that reflect individual preferences.

Full Color 3D Printing

With full color 3D printing, you can achieve realistic and vibrant multi-colored objects that bring your designs to life. Full-color 3D printing technologies allow for the creation of objects in multiple colors simultaneously, matching any tone and producing highly detailed and realistic parts. Technologies like binder jetting and material jetting are commonly used to achieve full-color 3D prints.

During the printing process, full-color 3D printers add color to the base material similar to a color 2D printer. This results in stunningly vivid and lifelike prints with smooth surfaces. However, it is important to note that entry prices for full-color 3D printing technologies can be high, making them less accessible for most users.

Currently, only one manufacturer offers a more affordable option for full-color FDM 3D printing. This technology allows you to produce colorful prints with ease while maintaining good detail resolution. It is suitable for applications that do not require a photo-realistic effect but still want vibrant and visually appealing objects.

Painting 3D Printed Parts

To achieve vibrant colors and fine details on your 3D printed parts, consider painting them with acrylic, oil, or spray paint. Painting your 3D printed parts offers a custom solution for achieving vivid colors and enhancing the overall appearance. Here are some key points to keep in mind when painting your 3D prints:

Preparing the surface

Before painting, it is important to prepare the surface of your 3D printed part. This may involve sanding any imperfections or using a primer to create a smooth base for the paint.

Choosing the right paint

Acrylic, oil, and spray paints are popular choices for painting 3D prints. Each type of paint has its own advantages and considerations, so be sure to choose one that suits your needs.

Applying multiple coats

To achieve an even color and coverage, it is often necessary to apply multiple coats of paint. Allow each coat to dry completely before applying the next layer.

Finishing touches

Once you have achieved the desired color and finish, consider applying a clear coat or varnish to protect the painted surface.

Hydrographics for 3D Printed Parts

Hydrographics is a unique method of applying printed designs to the surface of 3D printed parts. It involves printing an image on a polyvinyl alcohol film, which is then submerged in water and applied to the object. This technique can be used to add full-color patterns to 3D printed parts, allowing for customization and enhancing their appearance.

One interesting application of hydrographics is computational hydrographics. This technique combines 3D printing and hydrographics to create complex patterns that can’t be achieved with traditional methods. By utilizing this process, you can add intricate designs and unique color combinations to your 3D printed objects.

Hydrographics offers a unique way to add color and design to your 3D prints. It allows for vibrant and detailed patterns that can make your creations stand out. Whether you’re looking to personalize your phone case or create eye-catching decorations, hydrographic printing can help you achieve the desired effect.

Keep in mind that while hydrographics can produce stunning results, it requires careful attention to detail during the printing process. The film must be properly aligned with the object’s surface, ensuring that the design transfers accurately.

Applications for Color 3D Printing

When exploring applications for color 3D printing, you can save time and money by creating realistic prototypes. Color 3D printing opens up a world of possibilities for various industries and creative pursuits. Here are four key applications where color 3D printing can make a difference:

– Engineers and designers benefit from the ability to create accurate and vibrant prototypes. With color 3D printing, they can visualize their designs in a realistic way, identifying potential issues and making improvements before moving forward with production.

– Movie makers can turn digital models into props that look authentic on screen. By utilizing color 3D printing, they can bring their characters and sets to life with vivid colors and intricate details.

– Model makers have the opportunity to create vibrant miniatures for gaming or display purposes. Colorful 3D printed models add an extra level of realism and appeal to their creations.

– Medical professionals can produce anatomical models that accurately represent human anatomy. These models aid in surgical planning, education, and patient communication by providing a visual representation of complex structures in lifelike colors.

Color 3D printing offers versatility across various industries, allowing users to unleash their creativity while achieving professional results.

Direct Colour 3D Printing

Direct color 3D printing uses a filament with pre-existing colors to achieve bright and detailed prints. With this technology, you can create vibrant objects with good levels of detail. Direct color 3D printing is commonly used in FDM (Fused Deposition Modeling) printers, which are known for their affordability and ease of use.

When using direct color 3D printing, you have the option to print in a single color or multiple colors. FDM printers can be equipped with either a single extruder or multiple extruders, allowing for more complex color combinations. The slicing software plays an important role in setting up the print job and producing the G-code.

However, it’s important to note that direct color 3D printing does not allow for color mixing like some other technologies do. This means that achieving photo-realistic effects may be limited. Additionally, the process of switching out filaments during the printing process can be time-consuming and risky if not properly executed.

Overall, direct color 3D printing is suitable for applications that don’t require a photo-realistic effect but still need bright and colorful prints. It offers an affordable solution for achieving colorful objects with good detail levels.

Indirect Colour 3D Printing

Indirect color 3D printing applies color from an external source, offering a wide range of color options for achieving vibrant and realistic prints. With this technology, you have the ability to create colorful and detailed 3D printed objects. Here are some key points about indirect color 3D printing:

ColorJet technology

This method uses fine, sandstone-like powder and applies color during the printing process. It offers a wide range of colors and is suitable for designers, architects, and game character production. In order to achieve vibrant colors, the 3D files must include information about the desired colors and textures.

PolyJet technology

This technique utilizes liquid resin and UV curing to apply color between layers. It provides excellent detail and surface finish. Additionally, you can adjust the level of transparency of the colors according to your preference.

HP Jet Fusion

This innovative technology uses a binding agent to achieve evenly colored prints with good dimensional stability, water resistance, and ductility.

Mimaki machines

These printers are capable of using over 10 million colors, providing even more options for achieving your desired look.

Overall, indirect color 3D printing offers precision and realistic appearance in your prints. Whether you’re working on prototypes or professional models, this technology can help bring your designs to life with vibrant colors that accurately represent your vision.

Color Jet Printing

To achieve vibrant and realistic prints, consider ColorJet technology for your 3D printing needs. ColorJet technology has been around for over 20 years and offers a unique solution for achieving colorful prints. In the ColorJet printing process, powder is bound by colored glue to create multi-colored objects. This technology is suitable for figurines, anatomical models, and non-functional prototype mockups. It provides a range of colors but may not be suitable for parts requiring mechanical strength or water resistance.

ColorJet technology offers fair dimensional stability and value for money. It allows designers, architects, and game character producers to bring their creations to life with vibrant colors. To use this technology effectively, it’s important to include color and texture information in the 3D files.

With ColorJet technology, each layer of the object is created by spreading layers of material and applying color with printing heads. This process is repeated layer by layer until the final object is completed with vibrant colors that stand out.

If you’re looking for a reliable and cost-effective way to achieve colorful prints, ColorJet technology is definitely worth considering for your 3D printing needs.

PolyJet Printing

If you want high-resolution prints with fine details and a smooth surface finish, PolyJet printing is a great option for you. Here are some key points to consider:

– PolyJet technology uses liquid resin material to achieve high resolution and detail.

– The process involves applying layers of liquid resin that are cured with UV light.

– PolyJet printers can produce parts in vibrant colors, allowing for a wide range of color options.

– This technology is suitable for both functional and visual prototypes, as well as anatomical models and figurines.

With PolyJet printing, you can create intricate designs with stunning visual appeal. The high resolution and smooth surface finish make it ideal for applications where precision and aesthetics are important. Whether you need to prototype a new product or bring your artistic creations to life, PolyJet printing can deliver the results you desire.

Keep in mind that while PolyJet offers excellent print quality, it may not be the most cost-effective option for large-scale production due to the higher cost of materials and equipment. However, if you value quality over quantity and require highly detailed prints with vibrant colors, PolyJet printing is worth considering.