Hey there! Ever wondered why those pesky vertical lines keep showing up on your 3D prints? Well, in this article, we’re diving deep into the world of Fine Vertical Artifacts (FVAs) in 3D printing. These little lines can really affect the quality of your prints, but fear not! We’ll explore Trinamic chop tuning as a potential solution to eliminate FVAs. Stick around as we discuss firmware modifications, experimental Gcodes, and other important aspects like bed leveling and calibration. Let’s get those flawless prints you’ve been dreaming of!

The Impact of Fine Vertical Artifacts (VFAs) on Print Quality

You should be aware that fine vertical artifacts (VFAs) can significantly impact the quality of your prints on the Mk3 printer. These VFAs are vertical fine lines that can occur on both the x and y axes of printed objects. Reducing VFAs through mechanical adjustments is crucial to improving print quality. Troubleshooting VFAs on specific printer models is also important, as different printers may have varying characteristics when it comes to the visibility of these artifacts. It’s worth noting that VFAs can also affect print speed, as they can slow down the printing process. Optimizing slicer settings can help minimize the occurrence of FVAs in your prints. Additionally, filament quality plays a role in VFAs occurrence, so using high-quality filament is recommended for better print results.

Exploring Trinamic Chop Tuning as a Solution to VFAs

Exploring Trinamic chop tuning can potentially eliminate VFAs, as it has been considered as a solution for improving print quality on the Mk3 printer. This firmware modification allows for adjustments to be made using experimental Gcodes specifically designed for Trinamic chop tuning. Here are three reasons why you should consider implementing Trinamic chop tuning to mitigate VFAs:

- Enhanced Print Quality: By eliminating VFAs, you can achieve higher quality prints with smoother surfaces and fewer visible flaws.

- Improved Reliability: Firmware modifications and Trinamic chop tuning help optimize the zero crossings and waveform glitches, resulting in a more stable printing process.

- Reduced Noise: Adjusting the parameters through Trinamic chop tuning can also reduce audible stepper noise during printing, creating a quieter and more enjoyable experience.

Understanding the Mechanics of Fine Vertical Artifacts (VFAs

The visibility of VFAs can vary among printers due to various factors such as rod and bearing alignment issues. When it comes to understanding the mechanics of VFAs, several key aspects should be considered. Mechanical alignment plays a crucial role in the visibility of VFAs, as any misalignment can obscure their appearance. Waveform optimization is another important factor that can affect VFA visibility. By fine-tuning the waveform, you may be able to reduce or eliminate VFAs altogether. Additionally, nozzle height, extruder tension, and bed surface choice all contribute to the presence and clarity of VFAs in your prints. Taking these factors into account and making necessary adjustments can help improve the overall print quality and minimize the occurrence of VFAs.

| Key Factors | Impact on VFA Visibility |

|---|---|

| Mechanical Alignment | Can obscure VFAs |

| Waveform Optimization | Affects VFA appearance |

| Nozzle Height | Influences VFA clarity |

| Extruder Tension | Can impact VFA presence |

| Bed Surface Choice | Contributes to VFA visibility |

Firmware Modifications for Trinamic Chop Tuning

Firmware has been modified to enable Trinamic chop tuning, allowing for potential improvements in print quality by addressing the issue of Fine Vertical Artifacts (VFAs). This modification opens up new possibilities for eliminating VFAs and enhancing the overall printing experience. The impact of chop tuning on print quality is significant, with several parameters coming into play. Here are three key aspects to consider:

- Trinamic chop tuning parameters: These parameters play a crucial role in fine-tuning the printer’s performance and reducing VFAs.

- Firmware modifications for VFA elimination: By making specific changes to the firmware, it becomes possible to eliminate VFAs and achieve higher print quality.

- Experimental Gcodes for chop tuning: These Gcodes allow users to adjust the chop tuning parameters and observe their impact on print quality, providing valuable insights for further research on effectiveness.

Observations and Findings From Trinamic Chop Tuning

Through Trinamic chop tuning, researchers have made observations and found valuable insights on the impact of adjusting parameters for enhancing print quality and potentially eliminating VFAs. Fine vertical artifacts (VFAs) analysis revealed that VFAs are a common flaw affecting print quality on the Mk3 printer. The presence of VFAs can be observed on both the x and y axes of printed objects. Firmware modifications were made to enable Trinamic chop tuning, and experimental Gcodes were added to adjust parameters. The effectiveness of Trinamic chop tuning in reducing VFAs was inconclusive, with subtle differences observed when adjusting certain parameters. It was found that Trinamic drive current zero crossing issues and waveform reconstruction flaws contribute to VFAs. Further investigation is needed to optimize zero crossings and waveform glitches for a comprehensive solution to VFAs impacting print quality.

Uncovering the Underlying Causes of VFAs in 3D Printing

Now that you have explored the observations and findings from Trinamic Chop Tuning, it’s time to delve deeper into the underlying causes of VFAs in 3D printing. Understanding these causes is crucial for eliminating FVAs and improving print quality. Here are some key points to consider:

- Impact of FVAs on print quality:

- VFAs can significantly affect the visual appearance and smoothness of printed objects.

- They can create visible lines or artifacts on the surface, compromising the overall quality.

- Mechanics of FVAs:

- VFAs occur due to issues with stepper motor control and movement precision.

- Inaccurate positioning or irregular movements of the printer’s mechanics contribute to the formation of VFAs.

- Firmware modifications for FVAs:

- To address VFAs, firmware adjustments were made to enable Trinamic chop tuning.

- Experimental Gcodes were added to fine-tune parameters related to motor control and waveform reconstruction.

To effectively eliminate VFAs, it is essential to not only understand their impact on print quality but also focus on bed leveling and calibration as well as firmware modifications for precise motor control.

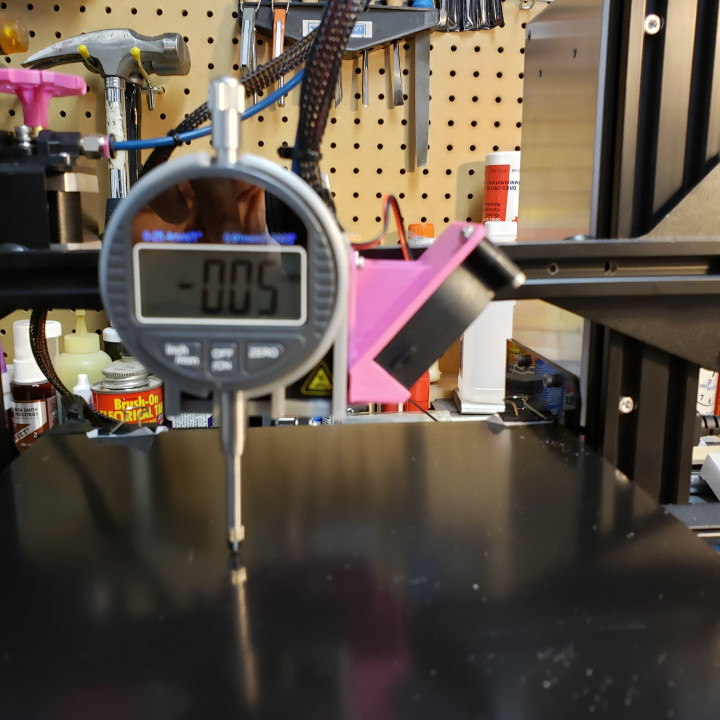

The Role of Bed Leveling and Calibration in Minimizing VFAs

Properly leveling and calibrating the bed is crucial in minimizing VFAs and improving print quality. To achieve this, use leveling blocks or items of the same height to ensure both sides of the X gantry are at the same level. Manually level the four corners of the bed, making sure to clean both the bed and nozzle beforehand. Heat up the bed and nozzle to printing temperature for accurate leveling. Use a 0.2 mm thick card or a feeler gauge to adjust the nozzle height, repeating the process two to three times for consistency across all corners. While auto bed leveling can compensate for uneven surfaces, manual bed leveling is still important, especially for BLTouch users who prioritize accuracy. After leveling, calibrate the Z offset using your printer’s built-in feature or by following a guide/tutorial. Always perform calibration with both nozzle and bed heated to printing temperatures for optimal results.

Belt Tightening and Extruder Calibration for Optimal Print Quality

To achieve optimal print quality, it is important to avoid overtightening the belts on your printer and to perform extruder calibration for accurate filament flow. Here are three key steps to consider:

- Check belt tension: Overtightened belts can lead to patterned side walls and other issues. Tighten the belts just enough to prevent slipping from the motor pulleys, but avoid overstretching them.

- Perform extruder calibration: Verify the measured values for extruder calibration and ensure there are no mechanical issues. Read a dedicated article on flow rate calibration and make necessary adjustments. Double-check the calibration after making any adjustments.

- Maintain nozzle cleanliness: Regularly clean your nozzle to prevent clogs or improper filament flow. Nozzle maintenance is crucial for consistent print quality.

Retraction Optimization and First Layer Techniques to Reduce VFAs

For better print quality and to minimize VFAs, it is important to optimize retraction settings and employ effective first layer techniques. Start by performing retraction calibration to find the optimal retraction value for your printer. Adjust the retraction speed, restart amount, and coasting settings for cleaner retractions. Make sure the PTFE tube is fixed in the coupler to ensure consistent results. Next, focus on first layer adhesion by adjusting the first layer height, flow rate, and extrusion width. Ensure that the first layer lines touch without any space between them. Avoid excessive filament extrusion to prevent elephants foot effect and find a balance between print height and adhesion. Additionally, pay attention to cooling techniques to improve print quality. Proper nozzle selection, moisture control for dry filament, and temperature optimization are also essential factors in reducing VFAs during 3D printing.

Filament Moisture Control and Temperature/Cooling Optimization for VFA-free Prints

Make sure you dry your filament properly to minimize moisture-related issues and optimize the temperature and cooling settings for VFA-free prints. To achieve the best results, consider the following:

- Filament storage techniques: Store your filament in airtight containers with desiccant packs to keep it dry and free from moisture absorption.

- Impact of ambient temperature on print quality: Ensure that your printing environment has a stable temperature, as fluctuations can affect the consistency of your prints.

- Cooling fan upgrades for better print results: Upgrade your cooling fans to improve airflow and prevent overheating during the printing process, resulting in cleaner and smoother prints.