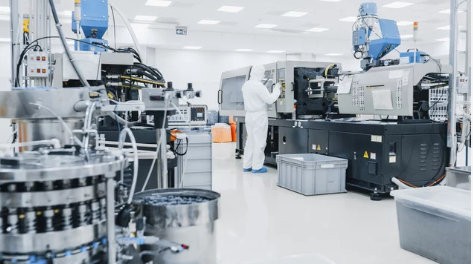

Welcome to the 3D printing lab, where you’ll witness the future of fabrication unfold before your eyes. In this article, you’ll explore the exciting world of 3D printing and its endless possibilities. Imagine creating unique, custom-shaped keys or personalized designs without additional time, cost, or tools. But it doesn’t stop at customization. 3D printing opens up new avenues for innovation and collaboration, resulting in groundbreaking creations like 3D printed midsoles or custom-designed guitars. Discover how 3D printing is revolutionizing the manufacturing landscape and its implications for the industry.

Complexity and Customization

When it comes to manufacturing complex and customized products, 3D printing offers a cost-effective and efficient solution. With 3D printing, there is increased security due to the ability to create unique and custom-shaped keys. The intricate geometries in locks and keys can enhance security measures. Additionally, 3D printing allows for personalized designs, ensuring a perfect fit for items such as hearing aids, dental braces, shoe inserts, and headphones. The customization process does not lead to an increase in manufacturing costs, making it an attractive option for businesses and consumers alike. Company logos and personalized designs can be easily printed, further enhancing the customization possibilities.

One of the main benefits of 3D printing is the cost reduction it offers. Complex items can be 3D printed without the need for additional tools, time, or cost compared to simpler ones. This makes 3D printing a viable option for businesses looking to streamline their manufacturing processes and reduce expenses. Furthermore, 3D printing enables the creation of custom-shaped keys, eliminating the need for expensive and time-consuming manual labor. Overall, 3D printing provides a cost-effective and efficient solution for manufacturing complex and customized products, offering increased security, perfect fit, and personalized designs, all while reducing costs.

Fast Prototyping and Innovation

With 3D printing, you can rapidly prototype and innovate, allowing for faster development and testing of products. The advancements in 3D printing technology have brought numerous benefits to rapid prototyping. Traditional prototyping methods often require a significant amount of time and resources, but with 3D printing, prototypes can be created in a matter of hours. This not only reduces the time required for development but also allows for instant testing and tweaking of products.

Moreover, 3D printing has opened up a world of creative design possibilities. The availability of 3D printers stimulates creativity and removes traditional manufacturing constraints. Complex geometries and unique shapes can be easily produced, leading to innovative and customized products. Additionally, 3D printing offers time and cost savings. By eliminating the need for tooling and reducing the production time, companies can save on manufacturing costs.

Looking ahead, the future potential for innovation with 3D printing is vast. As the technology continues to evolve, we can expect further advancements in materials, printing techniques, and capabilities. This opens up new opportunities for industries across the board, from aerospace to medical to automotive. With faster prototyping, creative design possibilities, and time and cost savings, 3D printing is poised to revolutionize the way products are developed and manufactured. The future holds tremendous potential for innovation in the field of fabrication.

Potential for New Products

The potential for new products in the field of fabrication with 3D printing is vast and exciting. 3D printing has already made waves in various industries, and its impact on fashion, jewelry, art, and furniture is no exception. In the fashion industry, designers are utilizing 3D printing to create unique and intricate designs that were previously impossible to achieve. From avant-garde runway pieces to customizable accessories, 3D printing is revolutionizing the way fashion is created and worn.

In the realm of jewelry, 3D printing allows for the production of intricate and personalized designs. This technology enables jewelers to create complex and detailed pieces that were once difficult to achieve through traditional manufacturing methods. It also allows for customization, allowing customers to create one-of-a-kind pieces that reflect their individual style and preferences.

In the art world, 3D printing has opened up new possibilities for artists to explore innovative techniques and materials. Artists can now bring their digital creations to life in three dimensions, pushing the boundaries of traditional art forms. From sculptures to installations, 3D printing is transforming the way art is created and experienced.

When it comes to furniture, 3D printing offers the potential for custom-designed pieces that perfectly fit individual needs and preferences. This technology allows for the creation of unique and personalized furniture that combines both form and function. From chairs to tables, 3D printing is reshaping the way furniture is designed and manufactured.

With its ability to create complex and customized products, 3D printing is paving the way for new and innovative creations in the fields of fashion, jewelry, art, and furniture. The possibilities are endless, and as the technology continues to advance, we can expect even more exciting developments in the future.

Implications for the Industry

In the rapidly developing field of 3D printing, the industry is being transformed by the innovative and efficient manufacturing process. The impact on manufacturing is significant, with 3D printing offering numerous benefits such as cost reduction, the use of innovative materials, and market potential. With 3D printing, manufacturers can reduce costs by eliminating the need for complex tooling and reducing waste in the production process. This can lead to more affordable products for consumers. Additionally, 3D printing enables the use of innovative materials, such as carbon fiber, which can enhance the performance and durability of products. This opens up new possibilities for design and functionality.

The market potential for 3D printing is vast, with industries like aerospace, automotive, medicine, defense, and construction already adopting the technology. As future advancements continue to improve the capabilities of 3D printing, the industry is poised for further growth and innovation. Overall, the implications for the industry are significant, with 3D printing revolutionizing the manufacturing process and offering exciting opportunities for businesses to thrive.

General Benefits of 3D Printing

Experience the numerous benefits of 3D printing, as it revolutionizes the manufacturing process and offers exciting opportunities for businesses to thrive. The general benefits of 3D printing are vast and impactful across various industries. One major advantage is the ability to create complex and customized products. With 3D printing, companies can manufacture intricate items without incurring additional costs, time, or tools. This opens up possibilities for unique and custom-shaped products like keys, locks, and hearing aids that can be tailored to individual customers for a perfect fit. Moreover, 3D printing allows for easy customization without increasing manufacturing costs, enabling the printing of company logos and personalized designs.

Another benefit of 3D printing is the speed and cost savings it offers in the prototyping process. Compared to traditional techniques, 3D printing allows for the rapid production of prototypes in a matter of hours. This instant testing and tweaking of products greatly accelerates the innovation process and reduces costs associated with prototyping.

Furthermore, 3D printing stimulates innovation and creativity by removing traditional manufacturing constraints. Companies can explore new design possibilities and experiment with non-rectangular shapes and printed electronics. This opens up opportunities for the development of new and unique products, such as custom-designed guitars and collaboration between companies to create customized products like 3D printed midsoles for running shoes.

Adoption of 3D Printing Phases

As you delve deeper into the world of 3D printing, it is important to understand the different phases of adoption that this revolutionary technology has gone through. The adoption phases of 3D printing can be categorized into four distinct stages: rapid prototyping and tooling, digital manufacturing and home fabrication, difficulties in capturing value, and rapid prototyping of adaptive business models.

The first phase, rapid prototyping and tooling, focused on using 3D printing for creating prototypes and manufacturing tools. This phase raised competition among manufacturers and allowed for faster and more cost-effective prototyping.

The second phase, digital manufacturing and home fabrication, brought about a technological revolution that disrupted traditional business models. It enabled the production of real products using 3D printing, leading to the potential for customization and value creation.

However, difficulties in capturing value offset the increase in value creation in the third phase. The disruptive nature of 3D printing made it challenging for businesses to find suitable business models and monetize the technology effectively.

The fourth phase, rapid prototyping of adaptive business models, highlights the potential of 3D printing to revolutionize business model innovation. Companies can adapt their business models to leverage the capabilities of 3D printing technology, leading to increased value creation and competitive advantage.

Impact on Business Models

You can see the impact of 3D printing on business models by examining how it has revolutionized the manufacturing industry. The technological revolution brought by 3D printing has led to the evolution of business models, creating value creation challenges for companies. With the ability to manufacture complex and customized products, 3D printing has paved the way for adaptive business models that can cater to changing customer demands.

This has the potential to revolutionize innovation ecosystems, as companies can now rapidly prototype and test their ideas, leading to faster innovation cycles. However, capturing value in this new landscape becomes extremely challenging due to the disruptive nature of 3D printing. Finding a suitable business model that allows companies to create and capture value is critical for success. As direct manufacturing and home fabrication become more prevalent, the potential for value creation increases, but so does the difficulty in capturing that value. In conclusion, 3D printing has the power to revolutionize business model innovation and transform the way companies create and capture value in the future.

Value Creation and Capture

To effectively create and capture value in the realm of 3D printing, it is essential to navigate the challenges posed by its disruptive nature. 3D printing has the potential to enable the creation of more value through its ability to manufacture complex and customized products. However, capturing this value can be extremely challenging due to the disruptive potential of direct manufacturing and home fabrication. The evolution of business models is crucial in order to monetize innovation and overcome the value capture challenges.

The disruptive nature of 3D printing poses unique value creation challenges. While it enables the production of more value through customization and complexity, traditional methods of capturing value may no longer be effective. This requires businesses to rethink their business models and find new ways to capture the value created by 3D printing.

The evolution of business models is necessary to fully exploit the disruptive potential of 3D printing. This involves adapting and innovating existing models to align with the capabilities and opportunities presented by 3D printing. By embracing the changes brought about by this technology, businesses can better position themselves to capture value and monetize their innovations.

Business Model Innovation

The first step in business model innovation for 3D printing is identifying the key stakeholders and their needs. Business model disruption is a result of transformative innovation brought about by the technological revolution of 3D printing. To address the value creation challenges posed by this disruptive technology, businesses must develop adaptive strategies that align with the unique capabilities and opportunities presented by 3D printing. This requires a deep understanding of the potential impact on strategies, business models, and innovation ecosystems.

The potential for 3D printing to revolutionize business model innovation is immense, as it enables the creation of new value propositions and the exploration of novel revenue streams. However, capturing value in this context becomes extremely challenging due to the disruptive nature of 3D printing. Businesses must find suitable business models that effectively capture the value created by this innovative technology. By embracing adaptive business models enabled by 3D printing, companies can unlock new opportunities for growth and success in the evolving landscape of fabrication.

Present State and Industrial Applications of 3D Printing

In the present state, 3D printing technology has gained widespread affordability and is extensively used in various industries such as aerospace, automotive, medicine, defense, and construction. In the aerospace industry, 3D printing offers fast delivery, low production quantity, design freedom, high precision prototypes, and easy customization. Real-world examples include spare parts manufacturing, rocket building, cost reduction, improved fuel efficiency, and production of components like jigs & fixtures, surrogates, and mounting brackets. In the automotive industry, 3D printing is used for prototyping, tooling, and end-parts production. It allows for improved automobile quality through rapid prototyping, customized tools for productivity improvement, and weight reduction using lightweight materials like carbon fiber.

The medical field extensively uses 3D printing for producing bones, exoskeletons, jawbones, cell cultures, ears, and more. Bioprinting techniques are used for organ and tissue production. Customized implants and prosthetics can be 3D printed using MRI scans. In the construction industry, 3D printing has been used since 2004, with methods like contour crafting and D-shaped 3D printers. Metal printing techniques are also being explored. Overall, the present state of 3D printing technology showcases its vast potential and its ability to revolutionize various industries.