Are you ready to delve into the world of high-performance 3D printing materials? Look no further than ULTEM. In this article, we’ll take you on a journey to explore the remarkable properties and applications of ULTEM, a thermoplastic known for its rigidity, lightweight nature, and exceptional resistance to heat, flame, UV, and solvents. Discover the secrets of printing with ULTEM, as well as its role in various industries. Join us in uncovering the cutting-edge technology of ULTEM printing.

ULTEM Properties and Applications

ULTEM is a thermoplastic material known for its rigid and lightweight properties. It has gained significant recognition in various industries due to its exceptional material properties. ULTEM offers advancements in terms of its dimensional stability and high strength-to-weight ratio. This makes it a popular choice for applications that require strong yet lightweight components. ULTEM has been extensively used in case studies across industries such as aerospace, automotive, electrical, medical, and culinary. Its flame retardancy and low toxicity have earned it certifications for use in aircraft, further contributing to its market growth.

ULTEM has proven to be a reliable substitute for steel and aluminum, particularly in the automotive industry, where maximizing fuel efficiency is crucial. Its chemical and heat resistance make it suitable for a wide range of applications, including cables, connectors, levers, engine components, and lighting. Moreover, ULTEM is certified for use in food production and medical environments, making it biocompatible and ideal for custom tools, baking equipment, and trays. It can also be sterilized, including through autoclaving, for medical sterilization purposes.

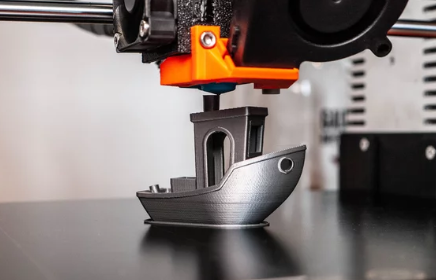

ULTEM in 3D Printing

When printing with ULTEM, it is important to consider the specific requirements and challenges of using this high-performance thermoplastic material. ULTEM filament extrusion for FDM printing requires high temperatures and an all-metal print head. To ensure successful prints, it is crucial to maintain a consistent chamber temperature to prevent warping. Post-processing techniques for ULTEM parts involve manual removal of support material, which can be time-consuming due to its strength and durability.

It’s worth noting that ULTEM material is expensive and has limited availability compared to other thermoplastics. However, its high-performance properties make it a popular choice in industries such as aerospace, automotive, and electrical. To achieve optimal results, it is recommended to use high-temperature 3D printers and keep the ULTEM filament dry. Overall, ULTEM in 3D printing provides durability and excellent mechanical properties, making it suitable for engineering applications that require high strength, dimensional stability, and resistance to heat and chemicals.

ULTEM in Manufacturing

To continue exploring the use of ULTEM in various industries, high-performance thermoplastic material is also widely utilized in manufacturing processes. When it comes to ULTEM in manufacturing, there are several key considerations to keep in mind. One of the challenges in machining ULTEM is the need for annealing prior to cutting in order to relieve internal stresses. Additionally, high-speed steel cutting tools are required for effective machining of ULTEM.

In terms of injection molding, proper material preparation and pre-drying are crucial for successful production. It is also important to maintain a high mold temperature during the injection molding process to ensure optimal results.

Both machining and injection molding are better suited for large volume production, making ULTEM an ideal choice for industries that require high-quality, high-performance components in large quantities.

Benefits of ULTEM Material

ULTEM material offers a range of benefits for high-performance 3D printing applications. Its properties make it an excellent choice for various industries and applications. Here are the key benefits of ULTEM material:

– Ultimate durability: ULTEM is known for its exceptional strength and durability, making it suitable for demanding applications. It has a high tensile strength and can withstand heavy loads and stress.

– Heat resistance: ULTEM has excellent thermal properties, with a high glass transition temperature and continuous use temperature. It can withstand temperatures up to 340°F, making it ideal for applications that involve exposure to high temperatures.

– Chemical resistance: ULTEM offers resistance to various chemicals, making it suitable for applications in industries such as automotive and electrical. It can withstand exposure to solvents, fuels, and other harsh chemicals without degrading or losing its properties.

In addition to these benefits, ULTEM is also lightweight, making it a great choice for applications that require weight reduction without compromising on strength. It is also biocompatible, making it suitable for medical applications such as custom tools, fixtures, and implants.

Down Points of ULTEM Material

One potential drawback of ULTEM material is its high cost. Due to its unique properties and high performance, ULTEM is more expensive compared to other thermoplastics. This can be a limiting factor for some users, especially those with budget constraints. Another consideration is the temperature requirements for printing with ULTEM. It requires a high temperature 3D printer with an all-metal print head to achieve optimal results. This may add to the overall cost of the printing process. Availability is also a concern as ULTEM filament may not be as widely accessible as other materials. Warping and shrinkage can be issues if ULTEM is not printed properly. It is important to maintain a consistent chamber temperature to prevent warping and ensure good printing quality. Despite these challenges, ULTEM offers durability and high-performance properties, making it a valuable material for various industries.

Tips for Printing With ULTEM Material

If you want to achieve optimal results when printing with ULTEM material, there are a few tips you should keep in mind:

– **Honeycomb infill**: Using honeycomb infill for lightweight parts can help reduce material usage and printing time while maintaining structural integrity.

– **Self-supporting angles**: Designing your parts with self-supporting angles can reduce the need for excessive support material, saving time and reducing post-processing efforts.

– **Chamber temperature**: Maintaining a consistent chamber temperature is crucial to prevent warping and ensure proper adhesion between layers. It is recommended to use a 3D printer with a heated chamber or employ an enclosure to regulate the temperature.

– **Annealing ULTEM parts**: Annealing ULTEM parts after printing can help relieve internal stresses and improve dimensional stability. This process involves heating the printed part to a specific temperature and slowly cooling it down.

– **Dry ULTEM filament**: ULTEM filament absorbs moisture from the environment, which can negatively impact print quality. It is essential to store ULTEM filament in a dry environment and use a filament dryer if necessary to remove any moisture before printing.

Industries That Use ULTEM Material

ULTEM material is widely utilized across various industries for its exceptional properties and performance. In the aerospace industry, ULTEM is used for flame retardant components, such as vents, cables, latches, and door handles. Its chemical resistance and lightweight nature make it suitable for automotive components, including cables, connectors, levers, engine parts, and lighting. ULTEM’s high-performance properties and durability make it a popular choice in the electrical industry for demanding applications.

ULTEM is also utilized in the food production industry for its heat resistance, making it ideal for producing heat-resistant products. In the medical industry, ULTEM is used for custom tools, fixtures, and biocompatible applications. It can be sterilized, including through autoclaving, making it suitable for medical devices.

These industries benefit from ULTEM’s exceptional properties, including its thermal stability, chemical resistance, and high strength-to-weight ratio. ULTEM material provides the necessary performance and reliability for these demanding applications.

ULTEM 3D Printers

When considering 3D printing with ULTEM, it is important to choose an appropriate ULTEM 3D printer for optimal results. Here are some key factors to consider:

High temperature capabilities:

– ULTEM filament extrusion requires high temperatures, so the 3D printer should be capable of reaching and maintaining these temperatures.

Material cost considerations:

– ULTEM is an expensive material, so it is important to consider the cost of the material and the efficiency of the printer in terms of material usage.

Print quality and accuracy:

– Look for a printer that can provide high print quality and accuracy to ensure that your ULTEM parts meet the desired specifications.

Post processing requirements:

– ULTEM parts often require manual removal of support material, so consider the post-processing requirements and whether the printer provides easy support removal.

Material availability:

– ULTEM is not as widely available as other 3D printing materials, so it is important to choose a printer that can accommodate ULTEM filament and ensure its availability.