Imagine a world where music is not only heard, but also felt beneath your fingertips. With the advent of 3D printing technology, this seemingly fantastical concept is becoming a reality. In “Pushing Boundaries: 3D Printing With Vinyl,” we explore how this groundbreaking innovation has the potential to revolutionize the manufacturing of vinyl records. By harnessing the power of 3D printing, independent artists can now create their own custom and collectible records at an affordable cost. Join us as we delve into the exciting possibilities that lie ahead in this brave new era of music production.

The Potential of 3D Printing in Vinyl Record Manufacturing

You can explore the potential of 3D printing in vinyl record manufacturing and see how it could revolutionize the production process. With 3D printing, production costs can be reduced significantly, making it more affordable for artists and independent labels to manufacture records. One of the key advantages is the customization options that 3D printing offers. Artists and collectors can create unique designs and limited-edition records tailored to their preferences. Additionally, on-demand manufacturing allows for smaller order quantities, eliminating the need for large minimum orders. However, one important aspect that needs to be addressed is sound quality assessment. Ensuring that 3D printed records meet the standards of traditional vinyl records is crucial. Lastly, there are intellectual property concerns that need to be considered when using this technology in record manufacturing.

Overcoming Challenges in Traditional Vinyl Record Production

The challenges faced in traditional vinyl record production can be overcome with the use of 3D printing technology. By adopting this innovative solution, the production process can be streamlined, leading to cost-effective alternatives and empowering independent artists. One of the key advantages of 3D printed records is the customization possibilities they offer. Artists and collectors can create unique designs and limited-edition records that cater to their specific preferences. To give you a better understanding, here’s a table showcasing how 3D printing technology addresses these challenges:

| Challenges | Innovative Solutions |

|---|---|

| Costly traditional production | Cost-effective 3D printing |

| Limited number of pressing plants | Independent artist empowerment |

| Long lead times | Streamlined production process |

| Large minimum order quantities | On-demand production capabilities |

| Lack of customization options | Customization possibilities |

With 3D printing technology, the barriers faced by traditional vinyl record manufacturing are being broken down, opening up new opportunities for artists and collectors alike.

Exploring the Benefits of 3D Printed Records

By adopting 3D printing technology, artists like yourself can explore a range of benefits when it comes to producing records. Here are four reasons why you should consider 3D printed records:

- Cost-effective production: With 3D printing, you can reduce the manufacturing costs associated with traditional vinyl record production. This opens up opportunities for independent artists who may have limited budgets.

- Customization options: 3D printing allows for greater flexibility in creating unique and personalized record designs. You can experiment with different shapes, textures, and colors to truly make your records stand out.

- Sound reproduction: While the fidelity and sound quality of 3D printed records still need assessment, advancements in technology are constantly being made to ensure better audio performance. You can contribute to this exciting development by exploring new materials and refining the printing process.

- Music industry acceptance: As more artists embrace 3D printed records, the music industry is gradually accepting this innovative approach to manufacturing. By joining this movement, you can be at the forefront of a growing trend that could reshape how music-related merchandise is produced and distributed.

Assessing the Feasibility of 3D Printing for Vinyl Records

Assessing the feasibility of 3D printed records involves evaluating the fidelity and sound quality, selecting appropriate materials, refining the technology to meet specific requirements, addressing intellectual property rights and licensing issues, and gaining acceptance from the music industry. To determine whether 3D printed records are a viable option, a cost effectiveness analysis is necessary. Material selection considerations play a crucial role in ensuring durability and sound reproduction. Intellectual property challenges must be overcome to protect artists’ rights and prevent unauthorized duplication. Acceptance and adoption by the music industry is essential for 3D printed records to gain traction. Additionally, it’s important to assess the impact on traditional vinyl record manufacturing as this new technology could disrupt existing production processes. Evaluating these factors will help determine if 3D printed records can become a mainstream alternative in the music industry.

| Factor | Description |

|---|---|

| Cost effectiveness analysis | Evaluate if producing 3D printed records is more cost-effective compared to traditional vinyl record manufacturing methods. Consider factors such as material costs, equipment expenses, labor requirements, and scalability of production process. |

| Material selection considerations | Choose appropriate materials that provide good audio quality while maintaining durability for long-lasting records. Explore different options including resins or polymers that can reproduce sound accurately and withstand repeated playback without significant degradation. |

| Intellectual property challenges | Address legal issues surrounding copyright protection for artists’ work when using 3D printing technology for record production. Develop strategies to secure intellectual property rights and prevent unauthorized duplication or distribution of copyrighted content. |

| Acceptance and adoption by the music industry | Gain support from key stakeholders in the music industry such as artists, labels, distributors, and consumers. Educate them about the benefits of 3D printed records including customization options, on-demand production capability, |

| and potential cost savings. | |

| Impact on traditional vinyl record manufacturing | Assess how the introduction of 3D printed records may disrupt or complement existing manufacturing processes. Consider potential implications for traditional vinyl record pressing plants, supply chain logistics, and market demand for traditional records. |

The Future Implications of 3D Printed Records

If you embrace the potential of 3D printed records, you could experience a shift in the manufacturing and distribution models of the music industry. Imagine the economic impact it could have as production costs decrease and indie artists have greater access to producing vinyl records. The artistic possibilities become endless as customization options are made available for both artists and collectors alike. Cultural implications arise as musicians have greater control over their merchandise and collectors can enjoy a wider range of unique and limited-edition records. Environmental considerations come into play with on-demand production, reducing waste from overproduction. However, adoption challenges remain in terms of assessing sound quality, refining the technology for vinyl record requirements, addressing intellectual property rights, and gaining acceptance from the music industry. But with these challenges overcome, the future implications of 3D printed records are promising indeed.

- Economic impact: Lower manufacturing costs open doors for indie artists.

- Artistic possibilities: Customization options allow for unique designs.

- Cultural implications: Musicians gain more control over their merchandise.

- Environmental considerations: On-demand production reduces waste from overproduction.

- Adoption challenges: Sound quality assessment and acceptance from the music industry pose obstacles to widespread adoption.

Introduction to 3D Printed Records Technology

Imagine experiencing the world of music in a whole new way with the introduction of 3D printed records technology. With this innovative technology, you can now customize your own vinyl records like never before. The possibilities are endless as you have the freedom to choose from a variety of 3D printed record materials and create unique designs that reflect your personal style. Not only does this technology offer customization options, but it also ensures durability, allowing you to enjoy your favorite tracks for years to come. However, as with any new technology, there are licensing considerations that need to be addressed to ensure artists’ rights are protected. Despite these challenges, the market potential for 3D printed records is immense, opening up new opportunities for both artists and music enthusiasts alike.

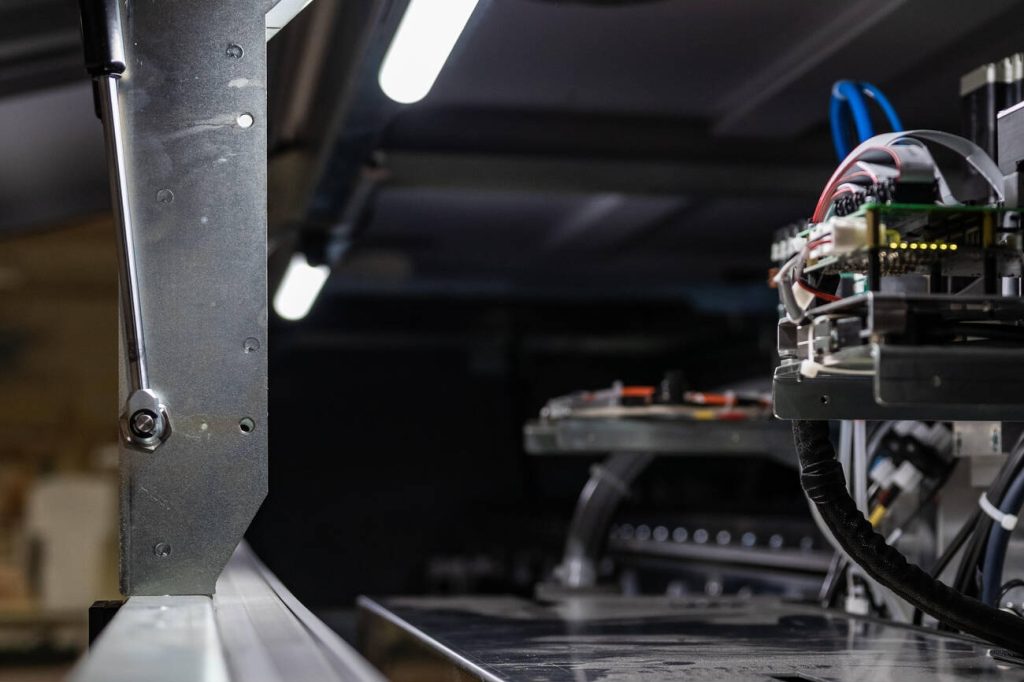

Understanding How a Record Works in 3D Printing

To understand how a record works in 3D printing, you’ll need to grasp the mechanics of the needle moving along the spiral groove on the record’s surface. This groove is what creates the audio signals that we hear when playing a record. Here are four key aspects to consider:

- Understanding groove mechanics: The shape and depth of the groove determine how accurately the needle can trace it and produce sound. Achieving a precise and recognizable groove shape is crucial for maintaining audio quality.

- Optimizing audio processing: Distortion and noise can occur during the 3D printing process, affecting audio quality. By refining audio processing techniques, we can minimize these issues and improve overall sound reproduction.

- Exploring custom record designs: With 3D printing technology, artists have the opportunity to experiment with unique and personalized record designs. This opens up new creative possibilities for collectors and musicians alike.

- Overcoming power issues and improving print quality: Power fluctuations in the printing process can disrupt print quality, leading to subpar records. Finding solutions to power issues will result in higher-quality prints and better overall performance.

Examining the Resolution of 3D Printed Records

Now let’s delve into the resolution of 3D printed records. When it comes to audio fidelity, the Objet printer used for printing records may not match the high resolution of real vinyl records. To create recognizable audio, it is crucial to approximate the groove shape accurately. Comparing images of modern vinyl record grooves and electron microscope images, we can see that microgroove records have a depth of around 1.1 mil, similar to the dimensions captured by the electron microscope. However, older 78s had larger grooves and needles compared to microgroove records. While 3D printed records may have lower audio quality than traditional vinyl, they still offer unique possibilities for custom record designs and experimentation in the music industry.

Limitations of 3D Printing Technology for Audio Quality

The audio quality of 3D printed records is lower compared to traditional vinyl due to the limitations of the printing technology. It’s important to understand these limitations in order to appreciate the potential of 3D printing with vinyl. Here are four key challenges that affect the audio quality of 3D printed records:

- 3D printing limitations: The resolution of 3D printers is still far from matching that of real vinyl records, resulting in lower fidelity.

- Audio quality challenges: Approximating the groove shape accurately is crucial for producing recognizable audio, but it’s difficult to achieve with current 3D printing technology.

- Improving resolution: Ongoing research and development focused on increasing the resolution of 3D printers may help improve audio quality in future iterations.

- Noise interference: Noise caused by adjacent print-heads on the printer can interfere with the audio signals, affecting overall sound reproduction.

To overcome these challenges and improve audio quality, adjustments may need to be made in terms of record dimensions and vertical amplitude of the groove.

Exciting Applications of 3D Printed Records in the Music Industry

You can explore exciting new possibilities in the music industry with 3D printed records. The advent of this technology has led to innovative record customization, allowing artists and collectors to create unique designs that were previously impossible. Collaboration in 3D printed records has also become a reality, as musicians, engineers, and designers come together to push the boundaries of what is possible with this medium. Furthermore, 3D printing offers a solution for rare and out-of-print record preservation by allowing for on-demand production of these hard-to-find gems. And let’s not forget about the mass production potential of 3D printed records – imagine being able to produce large quantities of records quickly and affordably! With 3D printed record designs, the future looks bright for the music industry.