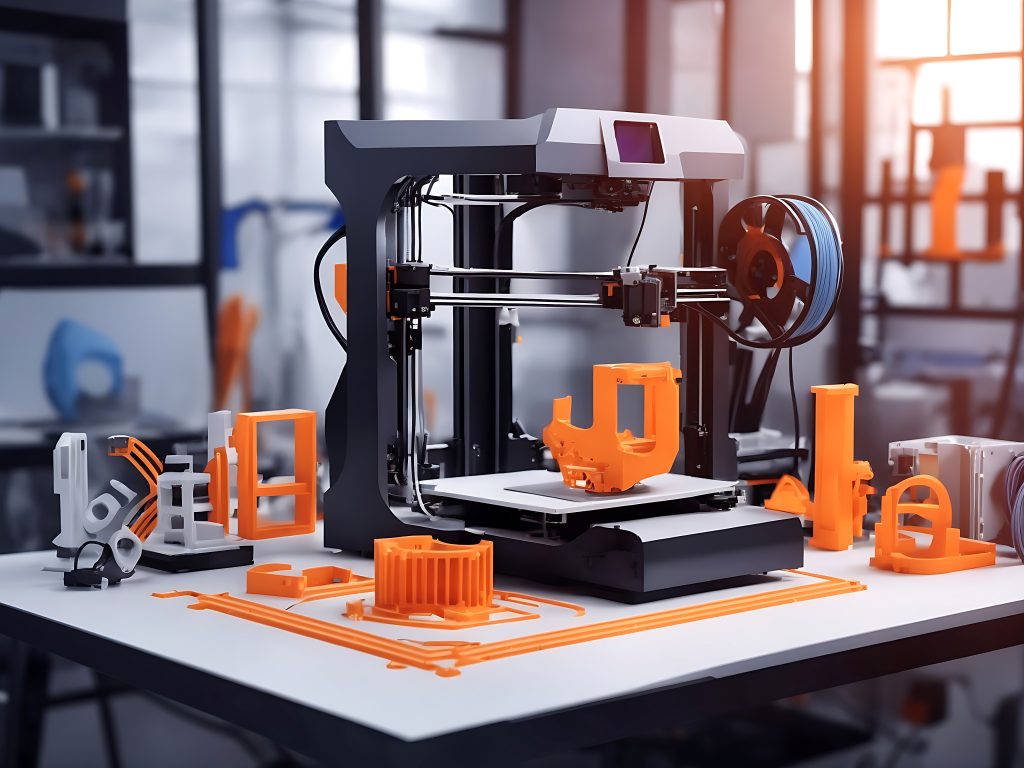

Are you ready to streamline your production process with 3D printing? Look no further. This article will guide you through placing a 3D printing order, allowing you to take advantage of the many benefits this innovative technology offers. From concept generation to material selection and prototyping, we’ll walk you through each step, providing valuable insights and tips along the way. With the ability to create complex geometries and reduce material waste, 3D printing has the potential to revolutionize your manufacturing approach.

Understanding 3D Printing Technologies

To understand 3D printing technologies, you need to grasp the various types of printers available on the market. 3D printing has revolutionized various industries with its applications in prototyping, manufacturing, and healthcare. The market trends for 3D printing are constantly evolving, with advancements in materials, software, and technologies.

When it comes to 3D printing applications, the possibilities are vast. It is widely used in the prototyping stage of product development, allowing for rapid iteration and design validation. In the healthcare industry, 3D printing is utilized to create personalized implants, prosthetics, and surgical models. The aerospace industry benefits from 3D printing by reducing weight and improving fuel efficiency of aircraft components.

The success of 3D printing heavily relies on the materials used. Different materials offer various properties and characteristics, impacting the final part. From metals to plastics, 3D printing materials continue to expand, providing more options for manufacturers and designers.

To operate 3D printers effectively, specialized software is required. These software programs enable the creation, modification, and optimization of 3D models, ensuring a seamless printing process. Keeping up with the latest 3D printing software advancements is crucial for staying competitive in the market.

Benefits of 3D Printing in Production

When considering the benefits of 3D printing in production, it is important to acknowledge how this technology revolutionizes the manufacturing process in various industries. The advantages of 3D printing in production are significant and can have a profound impact on businesses. Here are some key benefits:

– Customization Benefits:

– 3D printing allows for the creation of highly customized products that cater to individual needs and preferences.

– It offers the freedom of digital design, enabling complex geometries and intricate details that traditional manufacturing methods cannot achieve.

– Improved Efficiency and Cost Reduction:

– 3D printing streamlines the production process and reduces the time required to bring a product to market.

– It eliminates the need for tooling and reduces material waste, resulting in cost savings.

– Environmental Sustainability:

– 3D printing reduces the carbon footprint by minimizing material waste and energy consumption.

– It enables on-demand production, eliminating the need for large inventories and reducing excess stock.

Case studies have demonstrated the benefits of 3D printing in production. For example, Ford Motor Company has utilized additive manufacturing technologies to improve efficiency and reliability in part production. By 3D printing jigs and fixtures, Ford has streamlined its assembly line processes, leading to a more productive and efficient manufacturing process.

Steps to Placing a 3D Printing Order

To place a 3D printing order, you need to select the desired specifications and upload the digital file of the design. Customization options are available, allowing you to choose the material, color, and size of the object. Once you have made your selections, the 3D printing service will review your design for feasibility and provide a quote for the order. After confirming the order and payment, the production process begins. Throughout the process, you can track the status of your order using the order tracking feature provided by the service. Quality assurance measures are implemented to ensure that the final product meets your expectations. Once the production is complete, the item is carefully packaged and shipped to your specified address. The shipping and delivery process will vary depending on the location and shipping method chosen. If you have any questions or concerns during the process, customer support is available to assist you. Placing a 3D printing order is a straightforward process that offers customization options, order tracking, quality assurance, and reliable shipping and delivery.

Concept Generation and Designing for 3D Printing

To start the process of concept generation and designing for 3D printing, you must first generate a concept that solves the problem at hand. This concept can be generated by the client themselves or by the 3D printing service through CAD prototyping. The goal is to come up with ideas that address the specific problem or need. In-house engineering teams can also contribute to the concept generation process. Once the concept is established, the 3D printing service takes over and handles the rest of the process.

When designing for a 3D printer, there are several important considerations to keep in mind. These include 3D design considerations, design optimization, material compatibility, post-processing techniques, and cost analysis. Designing for a 3D printer offers more design liberties compared to traditional machining. This means that lightweighting options, complex geometries, and intricate features can be incorporated into the design. However, it is crucial to consider the available printing space of the printers and ensure that the part is appropriately designed for 3D printing.

In addition to design considerations, material selection and tolerance specification are also important factors to consider. The material selection impacts the properties and characteristics of the final part, and the tolerance specification determines the desired level of accuracy and precision. These factors affect the functionality and fit of the part, so careful consideration is necessary in order to meet the intended purpose of the part.

Material Selection for 3D Printing Orders

For your 3D printing order, the next step after concept generation and designing is to delve into the crucial process of material selection. Material selection plays a vital role in determining the final properties and characteristics of the printed part. Several factors need to be considered during this process, including cost considerations, material properties, printability factors, application-specific requirements, and sustainability considerations.

Cost considerations involve evaluating the price of the material and its impact on the overall project budget. Different materials have varying costs, and it is important to find a balance between affordability and meeting the desired specifications.

Material properties refer to the physical and mechanical characteristics of the chosen material. These properties include strength, flexibility, heat resistance, and durability. It is essential to select a material that will meet the specific requirements of the intended application.

Printability factors involve considering the compatibility of the material with the 3D printing technology being used. Each printing technology has its own limitations and requirements, and the material must be suitable for the chosen printing method.

Application-specific requirements refer to any unique needs or specifications that the printed part must meet. These requirements could include factors such as chemical resistance, electrical conductivity, or biocompatibility for medical applications. The material selection should align with these specific requirements.

Sustainability considerations involve evaluating the environmental impact of the chosen material. It is important to choose materials that are recyclable, biodegradable, or have a low carbon footprint to minimize the environmental impact of the 3D printing process.

Tolerance Specification for 3D Printing Orders

Specify the desired level of accuracy and precision for your 3D printing order by determining the tolerance requirements. Tolerance specification refers to the acceptable deviation from the intended dimensions of the final part. To effectively specify tolerances for your 3D printing order, consider the following design considerations:

– Material compatibility: Different materials have different properties and limitations. Ensure that the chosen material is suitable for achieving the desired tolerances.

– Design considerations: The complexity of the design, such as intricate features and geometries, can impact the achievable tolerances. Take into account the limitations of the chosen 3D printing technology.

In addition, consider the following quality control and production scalability factors:

– Quality control: Implementing quality control measures throughout the production process helps ensure that the final parts meet the specified tolerances. Regular inspections and testing can identify and address any deviations.

– Production scalability: Consider the scalability of the 3D printing process. As the production volume increases, maintaining consistent tolerances becomes crucial. Ensure that the chosen 3D printing service provider can handle large-scale production while maintaining the desired level of accuracy.

Post-processing techniques can also influence the final tolerances:

– Post-processing techniques: Certain post-processing techniques, such as polishing or sanding, can improve the surface finish and dimensional accuracy of the printed parts. Consider the need for post-processing and its impact on the specified tolerances.

Prototyping With 3D Printing

When prototyping with 3D printing, you can quickly create physical pieces for testing and evaluation, allowing you to iterate, troubleshoot, and refine your designs with ease. 3D printing offers rapid prototyping capabilities, which means you can produce multiple iterations of your design in a short amount of time. This allows for faster design validation and reduces the overall time it takes to bring a product to market.

One of the key advantages of 3D printing for prototyping is the design freedom it offers. With traditional manufacturing methods, there are often limitations on the complexity and intricacy of the design. However, with 3D printing, you have the freedom to create complex geometries and incorporate intricate details into your prototypes.

In addition to design freedom, 3D printing is also cost-effective for prototyping. Traditional manufacturing methods often require expensive tooling and setup costs, which can be prohibitive for small-scale prototyping. With 3D printing, you can create prototypes directly from a digital file, eliminating the need for expensive tooling and reducing the overall cost of prototyping.

Material selection is another important consideration when prototyping with 3D printing. Different materials have different properties and characteristics, and selecting the right material for your prototype is essential for accurate testing and evaluation. 3D printing service providers offer a wide range of materials to choose from, allowing you to select the material that best suits your prototyping needs.

Challenges and Future of 3D Printing

To fully understand the challenges and future of 3D printing, it’s important to regularly assess the advancements and limitations of this innovative manufacturing technology. 3D printing has already made a significant impact on the healthcare industry, with applications such as personalized implants, prosthetics, and surgical models. However, there are several challenges that need to be addressed for further progress.

One of the major challenges is scaling up 3D printing production. While 3D printing is capable of producing complex and customized objects, it is still limited in terms of volume and speed. Increasing production capacity without compromising quality and efficiency remains a hurdle.

Another challenge involves the intellectual property implications of 3D printing. The ease of replicating and sharing digital designs raises concerns about copyright infringement and unauthorized reproduction of patented products. Protecting intellectual property rights in the age of 3D printing is a complex and evolving issue.

Innovations in 3D printing materials are also crucial for the future of this technology. Advancements in materials with improved strength, durability, and flexibility will expand the range of applications for 3D printing. Research and development efforts are focused on developing new materials that meet the requirements of different industries.

Looking ahead, the future applications of 3D printing technology are vast. From construction to space exploration, 3D printing has the potential to revolutionize various industries. As the technology continues to evolve, we can expect to see advancements in areas such as bioprinting, nanotechnology, and sustainable manufacturing.

Advantages of 3D Printing in the Automotive Industry

When it comes to the automotive industry, 3D printing offers several advantages. Firstly, it allows for customized design, giving manufacturers the flexibility to create unique and tailored parts. Secondly, it saves time in the production process, as 3D printers can quickly create prototypes and functional parts. Lastly, 3D printing reduces costs by eliminating the need for traditional tooling and allowing for the reuse of materials. Additionally, 3D printing promotes sustainability by minimizing waste and optimizing resource utilization.

Customised Design

You can take advantage of customized design options in the automotive industry with 3D printing. This technology offers a range of benefits that enhance the design process and create personalized products. Here are some key advantages:

– Customization options: 3D printing allows for the creation of unique designs tailored to individual needs and preferences.

– Design freedom: With 3D printing, there are fewer limitations on complex geometries and intricate details, enabling innovative and creative designs.

– Manufacturing flexibility: 3D printing offers the flexibility to easily modify CAD files and make design improvements without the need for expensive tooling changes.

– Product uniqueness: By leveraging 3D printing, automotive manufacturers can differentiate their products by offering customized and one-of-a-kind designs.

These advantages of customized design through 3D printing help automotive companies stay ahead in a competitive market, meet customer demands, and deliver innovative and personalized products.

Time Saving

Save time in the automotive industry with the advantages of 3D printing. The implementation of 3D printing technology in the automotive industry offers significant time-saving benefits. Time management is critical in any production process, and 3D printing allows for efficient process optimization. With traditional manufacturing methods, the production of customized parts can be time-consuming and costly. However, 3D printing enables the creation of complex geometries and customized designs with ease, resulting in enhanced productivity and efficiency. Order fulfillment is also expedited as 3D printing enables on-demand production, eliminating the need for large inventories. By utilizing 3D printing technology, the automotive industry can improve time management, enhance productivity, and streamline the overall production process.

Reduced Costs

By embracing 3D printing technology in the automotive industry, significant cost reductions can be achieved. This technology offers cost savings and financial benefits through various cost reduction strategies and cost-effective solutions. Here are two key advantages of 3D printing in the automotive industry:

– Production Efficiency:

– 3D printing enables on-demand production, eliminating the need for large inventories and reducing storage costs.

– It allows for faster turnaround times compared to traditional manufacturing methods, leading to improved production efficiency.

– Customized Tooling:

– 3D printing offers high customization with the freedom of digital design, reducing the cost of customized tooling.

– The reuse of materials in 3D printing further contributes to cost savings.

Sustainability

Achieve environmental sustainability in the automotive industry with the advantages of 3D printing technology. 3D printing offers several benefits that contribute to sustainability efforts in the automotive sector. One key advantage is the reduction in material waste compared to traditional manufacturing methods. 3D printing allows for precise and efficient use of materials, minimizing waste and optimizing resource consumption. Additionally, 3D printing enables the use of eco-friendly materials, further reducing the environmental impact of automotive production. Another aspect of sustainability in 3D printing is the availability of recycling options. Unused or defective parts can be easily recycled and reprinted, reducing the need for new materials. By embracing 3D printing technology, the automotive industry can make significant strides in achieving sustainability goals and minimizing its ecological footprint.

Real World Case Study: Ford Motor Company

Ford Motor Company’s utilization of additive manufacturing technologies has revolutionized its production processes. The implementation of 3D printing has brought about significant efficiency improvements and led to more reliable production processes for the company. The impact of 3D printing on the automotive industry has been substantial, and Ford Motor Company has reaped numerous benefits as a result.

– Efficiency improvements:

– 3D printed jigs and fixtures have simplified and sped up assembly line processes, contributing to a streamlined and productive workflow.

– Faster production of complex parts through 3D printed molds and dies has enhanced the reliability and repeatability of Ford’s production processes.

– Benefits for Ford Motor Company:

– The adoption of 3D printing has revolutionized Ford’s production processes, leading to faster and more reliable part production.

– The use of 3D printed jigs and fixtures has simplified and accelerated assembly line processes, resulting in improved efficiency and productivity.