Are you curious about the 3D printing process? It’s simpler than you might think!

The 3 basic steps of 3D printing are CAD model creation, slicing, and printing.

We’ll walk you through each step so you can get started on your 3D printing journey.

CAD Model

The first step of 3D printing is creating a CAD model, which serves as the blueprint for the physical object to be printed. It’s important to understand the importance of CAD modeling in 3D printing and to be aware of common challenges.

Your design must be accurate and detailed to ensure quality printing. The model must be converted into a printer-compatible file format like STL, which contains instructions for the printer on where to place each layer of material. It must also be free from errors and inconsistencies.

Additionally, complex shapes and features must be simplified for efficient printing. Utilizing the proper CAD software and techniques will help you create a successful 3D printed part.

Slicing

You need to slice your 3D model using slicing software before printing. Slicing is the process of breaking the 3D model into hundreds or thousands of horizontal layers, which the 3D printer will use to create the final object.

There are various slicing techniques available, and it is important to understand the best practices for slicing software in order to get the best results. The main goal of slicing is to create the most efficient and accurate path for the printer to follow while creating the object.

The slicer will generate a G-code file, which contains instructions for the printer and includes the coordinates for each layer. The slicing process can be time-consuming, but it is necessary to ensure that the 3D printed object is of the highest quality.

Setting up the Machine

Ensure the 3D printer is clean and free from residue before setting it up.

Choosing the right printer is important and troubleshooting tips can help. For instance, the calibration process is critical and must be done regularly to ensure accuracy. The materials used must also be compatible with the printer.

It is also important to pay attention to the settings for the slicing software and the printer. During the setup process, it is important to pay attention to the details and configure the printer and material settings correctly.

Lastly, regular maintenance is essential to ensure the printer is running optimally and producing quality prints.

3D Printing

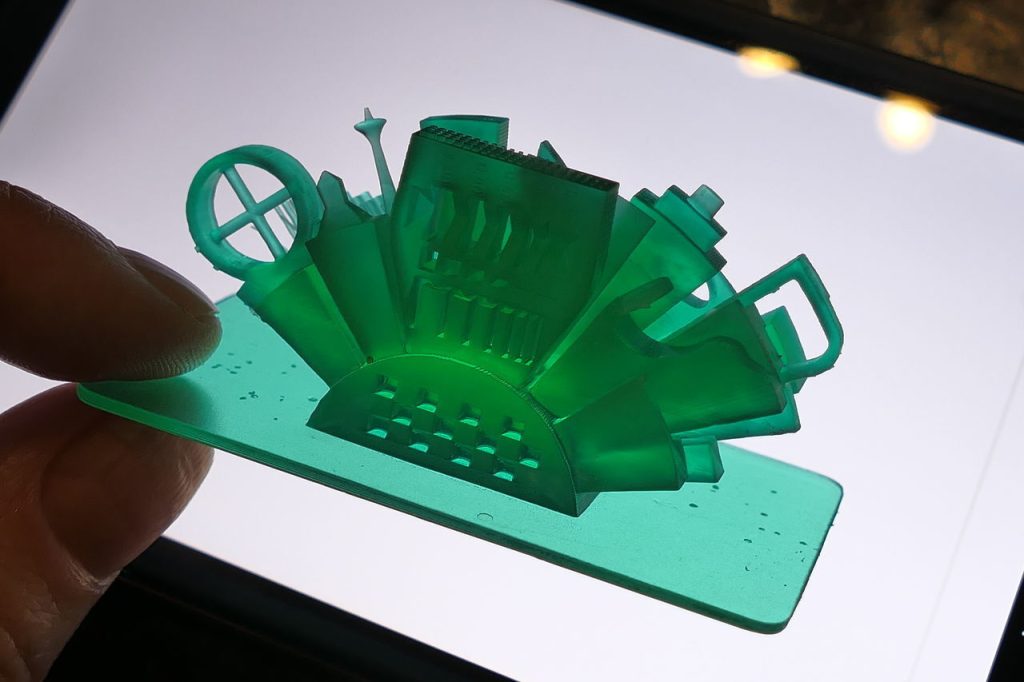

3D printing is an additive manufacturing technology that builds physical objects layer by layer. It has the potential to revolutionize the way we create new products and services. From jewelry and automotive parts to medical implants and food products, 3D printing applications have made advancements in 3D printing technology possible.

With 3D printing, objects can be created with a variety of materials, including metals, plastics, and ceramics. This technology allows for the production of complex parts with less waste and cost. It is also used for rapid prototyping, which helps speed up the product development process.

Additionally, 3D printing can be used to make custom parts and components, making it a great option for small businesses and entrepreneurs. This revolutionary technology is quickly changing the way we make and design products.

Post Processing

Once you have completed the 3D printing process, post-processing is the next step. It is of vital importance for 3D printed objects, as it helps to refine the look and feel of the finished products.

There are a number of techniques that can be used in post-processing, such as sanding, painting, adding surface treatments, and smoothing agents. Sanding can be used to remove any extra material or bumps left from the printing process, while painting and coating can help give the object a more finished look.

Surface treatments such as vapor smoothing can help to make the surface of the object smoother, while smoothing agents can be used to give the object a glossy finish.

Post-processing is a key element of the 3D printing process, and essential for achieving desired results.

Overview of the Process

You can gain an understanding of the 3D printing process by learning about the various stages involved.

The process begins with the creation of the CAD model, which is then converted into a printer-compatible format such as STL.

This is followed by slicing the model into layers using slicing software, and setting up the 3D printer.

The printer then builds the object layer by layer, using the appropriate technology.

The final step is post-processing, which can involve support removal, sanding, priming, and painting.

The benefits and applications of 3D printing technology are vast, ranging from consumer goods to industrial production.

However, there are still some challenges and limitations associated with 3D printing that need to be addressed.