The world of 3D printing has revolutionized manufacturing and design processes, offering endless possibilities for creators and innovators. At the heart of this rapidly evolving industry are 3D printing hubs, playing a pivotal role in connecting designers, manufacturers, and end-users.

In this discussion, we will dive deep into the concept of hubs in the world of 3D printing and explore their evolution from prototyping to producing end parts.

Understanding Hubs in the World of 3D Printing

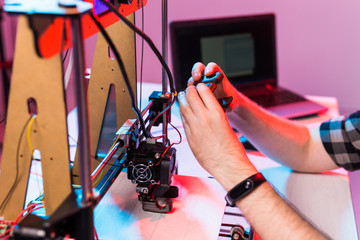

In the context of 3D printing, hubs can be defined as platforms or physical spaces that facilitate the collaboration between designers and manufacturers. They act as intermediaries, bridging the gap between those who have the expertise in designing and those who possess the necessary manufacturing hubs capabilities. Hubs come in various forms, including online platforms, physical spaces, and hybrid models combining both.

Online hubs, such as 3D Hubs 3D printing and Shapeways, connect designers with local manufacturing services. These platforms provide a seamless experience, allowing designers to upload their 3D models and connect with a network of verified manufacturers who can bring their designs to life. On the other hand, physical hubs like Fab Labs and TechShop offer access to advanced machinery, expertise, and training, empowering individuals to create their own prototypes and end parts.

The Evolution of Hubs: From Prototypes to End Parts

In the early days of 3D hubs printing, a hubs company primarily focused on prototyping. Designers could quickly iterate their ideas and create physical prototypes at a fraction of the time and cost compared to traditional manufacturing methods. However, as 3D print hubs technology advanced, so did the capabilities of these hubs.

Advancements in materials, such as high-strength polymers and metal alloys, have opened the doors for hubs to produce end parts with exceptional quality and durability. This shift has allowed businesses to streamline their supply chains, reduce inventory costs, and even customize products on-demand. However, it’s important to note that while hubs have the potential to produce end parts, there are still certain limitations and challenges to consider, such as production scalability and material selection.

Exploring Different 3D Printing Hubs

Let’s take a closer look at some popular online and physical hubs in the world of 3D printing:

1. Online Hubs

- 3D Hubs: With a vast network of manufacturing partners worldwide, www 3D Hubs connects designers with local manufacturing services. Designers can upload their 3D models, choose from a wide range of materials and finishes, and have their designs manufactured locally, reducing shipping times and costs.

- Shapeways: Shapeways offers a hubs website marketplace for customizable 3D printed products, allowing designers to sell their creations directly to consumers. It provides a user-friendly platform where designers can upload their 3D models, set their own prices, and tap into a global customer base.

2. Physical Hubs

- Fab Labs: Fab Labs are community-driven spaces for innovation and fabrication. Equipped with a range of tools, including 3D printers, laser cutters, and CNC machines, Fab Labs provide individuals with access to advanced machinery, expertise, and a supportive community.

- TechShop: TechShop is a membership-based workshop that grants access to advanced machinery, training, and workspace. With locations in various cities, TechShop empowers individuals to turn their ideas into reality, whether it’s prototyping new inventions or producing end parts for small-scale production.

The Future of Hubs in 3D Printing

As technology continues to advance, we can expect exciting developments in the field of 3D printing cnc hubs. Some emerging trends include the integration of artificial intelligence for design optimization, the rise of hybrid hubs that combine online platforms with physical spaces, and the exploration of new materials and printing techniques.

Hubs are also expected to have a significant impact on various industries, such as healthcare, automotive, and aerospace. From producing customized medical implants to creating lightweight and complex automotive components, 3D printing hubs parts have the potential to disrupt traditional manufacturing processes and revolutionize these sectors.

However, along with these opportunities, there are challenges to address, including intellectual property concerns, regulatory frameworks, and ethical considerations. As the adoption of 3D hubs inc continues to grow, it’s crucial to ensure that proper guidelines and standards are in place to protect the interests of all stakeholders involved.

Hubs play a vital role in the world of 3D printing, connecting designers with manufacturers and providing access to advanced machinery and expertise. From the early days of prototyping to the production of end parts, hubs have evolved alongside advancements in technology. As the 3D printing industry continues to expand, it is crucial for individuals and businesses to embrace hubs as a means to accelerate innovation, streamline