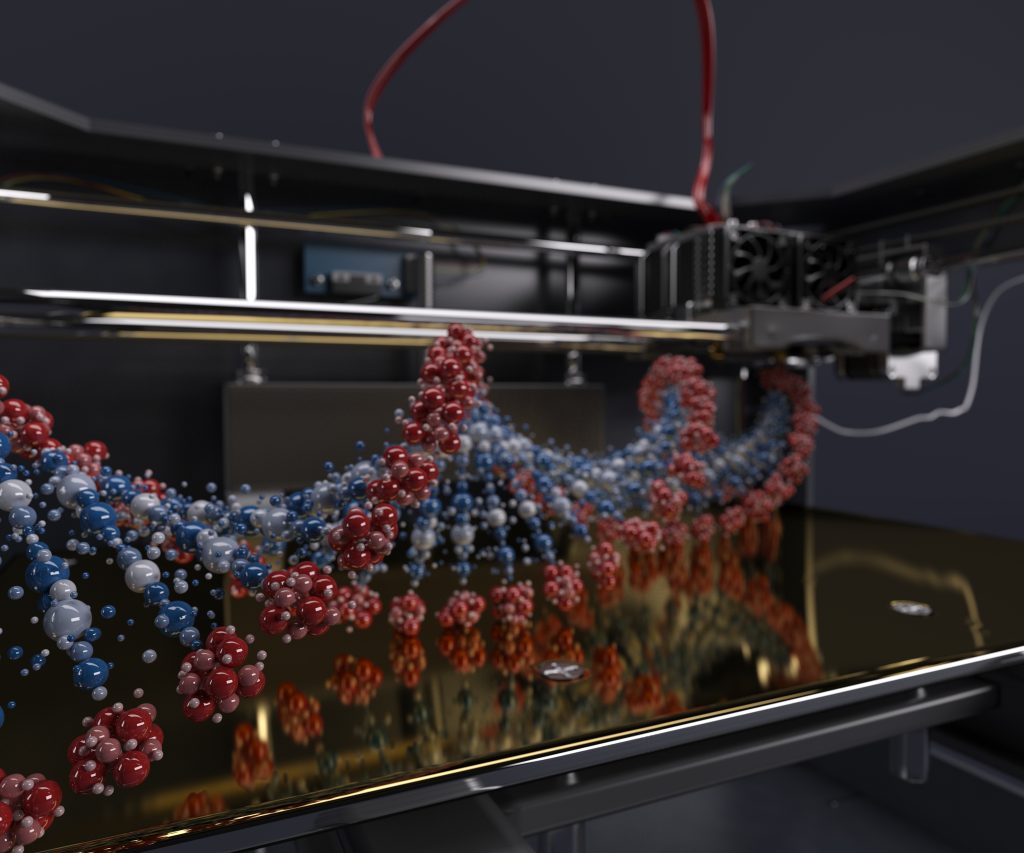

Curious about the latest in 3D printing? Imagine creating intricate designs on glass. Glass 3D printing is revolutionizing industries, offering customization and personalization. In this article, explore the advantages, applications, challenges, and future developments of 3D printing on glass. One advantage is the excellent optical properties, like transparency and light transmission. Glass 3D printing allows for complex geometries and reduces material waste. Challenges include specialized equipment and achieving high-resolution prints. Join us as we delve into the exciting world of 3D printing on glass surfaces.

Advantages of Glass 3D Printing

Glass 3D printing offers a uniquely customizable and precise method for creating objects using glass material. The advantages of glass 3D printing are numerous. Firstly, glass 3D printed objects have excellent optical properties, such as transparency and light transmission, making them perfect for applications in architecture, jewelry, and optical components. Additionally, glass 3D printing enables the creation of complex geometries that are difficult or impossible to achieve with traditional glass manufacturing methods. This opens up possibilities for innovative designs and customization. Glass 3D printing also reduces material waste compared to traditional glass manufacturing techniques, making it a more sustainable option.

However, there are challenges and limitations to glass 3D printing. The process requires specialized equipment and expertise, making it less accessible than other 3D printing methods. Achieving high-resolution prints can be challenging due to the viscosity of molten glass. The cost of glass 3D printing may also be higher compared to traditional glass manufacturing techniques. Furthermore, the mechanical properties of 3D printed glass objects may differ from those produced using traditional methods.

In terms of future developments, researchers are exploring new glass compositions and formulations to enhance the properties of 3D printed glass objects. Advances in glass 3D printing technologies aim to improve print speed and resolution. Integration of glass 3D printing with other additive manufacturing techniques, such as multi-material printing, is also being investigated. The development of user-friendly glass 3D printing systems may increase accessibility and adoption. Overall, glass 3D printing has the potential to revolutionize various industries and pave the way for innovative designs and applications.

Types of Glass for 3D Printer Beds

When it comes to choosing glass for your 3D printer bed, two popular options are borosilicate glass and clear float glass. Borosilicate glass is highly durable, chemically resistant, and consistently flat and smooth, making it the ideal choice for 3D printer beds. On the other hand, clear float glass is another option that offers a flat surface and good scratch resistance. Both types of glass provide the necessary qualities for successful 3D printing on glass surfaces.

Borosilicate Glass

To achieve optimal results when 3D printing on glass surfaces, it is important to consider using borosilicate glass as your preferred type of glass for the printer bed. Borosilicate glass is highly durable and chemically resistant, making it ideal for the glass printing process. Its low coefficient of thermal expansion allows for easy removal of completed parts, as it expands and contracts minimally during heating and cooling. Borosilicate glass also exhibits supreme thermal shock resistance, allowing it to withstand high temperatures without cracking or breaking. In terms of glass bed adhesion, borosilicate glass provides a consistently flat and smooth surface, ensuring that prints adhere well. When using glass filament and employing glass 3D printing techniques, the use of borosilicate glass can lead to superior results with its reliability, chemical resistance, and flatness.

Clear Float Glass

For the best results when 3D printing on glass surfaces, consider using clear float glass as your preferred type of glass for the printer bed. Clear float glass offers several advantages for glass 3D printing.

Advantages of clear float glass:

– High transparency and light transmission, making it ideal for creating glass 3D printed prototypes with excellent optical properties.

– Consistently flat surface ensures precise and accurate printing results.

– Superior durability and resistance to chemicals, making it suitable for glass 3D printing in the automotive industry.

– Versatile material for glass 3D printing in art and design, allowing for the creation of intricate and transparent designs.

– Cost-effective option, minimizing waste and requiring minimal maintenance.

Clear float glass is a reliable choice for glass 3D printing techniques, enabling the production of high-quality glass 3D printed objects in various industries, from automotive to art and design.

Benefits of 3D Printing on Glass From Swift Glass

Experience the numerous benefits of 3D printing on glass surfaces with Swift Glass. Swift Glass is a trusted company known for fabricating quality glass parts, offering a wide range of applications for glass 3D printing. One of the advantages of 3D printing on glass is the high level of quality and durability it provides. Swift Glass uses borosilicate glass, which ensures a level substrate and consistently even layers. This type of glass has excellent thermal shock resistance, allowing it to withstand high temperatures without cracking or breaking. Additionally, borosilicate glass is resistant to solvents, making it easy to clean and maintain.

Swift Glass also offers the advantage of being ISO 9001:2015 certified and ITAR registered, ensuring that their 3D printing services meet the highest quality standards. The testimonials from satisfied customers, such as Braden Bills, highlight the ability to achieve perfectly shaped glass objects through Swift Glass.

Applications of Glass 3D Printing

Glass 3D printing offers a wide range of applications in various industries, allowing you to create unique and intricate glass objects. Here are the advantages and possibilities of glass 3D printing:

– Advantages:

– Excellent optical properties: Glass 3D printed objects have transparency and light transmission, making them ideal for architectural applications and optical components.

– Customization possibilities: Glass 3D printing enables the creation of complex geometries and personalized designs.

– Material waste reduction: Compared to traditional glass manufacturing techniques, glass 3D printing reduces material waste.

– Architectural applications: Glass 3D printing is used to create unique glass facades and structures in architectural design.

– Biomedical applications: Glass 3D printing has potential applications in the biomedical field for the fabrication of glass implants and lab equipment.

– Decorative glass objects: Glass 3D printing is utilized in the production of decorative glass objects such as vases and sculptures.

– Jewelry production: Glass 3D printing is employed in the creation of jewelry, including rings, earrings, and pendants.

Glass 3D printing opens up new possibilities for customization and design in various industries, while also reducing material waste. Its versatility and unique optical properties make it a valuable tool for creating intricate glass objects.

Challenges and Limitations of Glass 3D Printing

When printing on glass surfaces, you may encounter certain challenges and limitations that can affect the overall 3D printing experience. Glass 3D printing requires specialized equipment and expertise, making it less accessible than other 3D printing methods. The process of glass 3D printing can be time-consuming, as glass materials often require high-temperature processing and cooling. Achieving high-resolution prints with glass 3D printing can be challenging due to the viscosity of molten glass. Glass 3D printing may result in higher costs compared to traditional glass manufacturing techniques. The mechanical properties of 3D printed glass objects may be different from those produced using traditional methods.

Despite these challenges and limitations, glass 3D printing techniques are continually evolving, driven by innovation and the desire to overcome these obstacles. Researchers are exploring new glass compositions and formulations to enhance the properties of 3D printed glass objects. Advances in glass 3D printing technologies aim to improve print speed and resolution. Integration of glass 3D printing with other additive manufacturing techniques, such as multi-material printing, is being investigated. The development of user-friendly glass 3D printing systems may increase accessibility and adoption. With ongoing advancements, glass 3D printing has the potential to revolutionize various industries, offering new possibilities for intricate and transparent designs.

Future Developments in Glass 3D Printing

As glass 3D printing continues to evolve, future developments in this field hold the potential to revolutionize various industries by offering new possibilities for intricate and transparent designs. The following potential advancements in glass 3D printing are being explored:

– Glass composition: Researchers are investigating new glass compositions and formulations to enhance the properties of 3D printed glass objects. By tailoring the composition, it may be possible to achieve improved strength, durability, and optical properties.

– Additive integration: Integration of glass 3D printing with other additive manufacturing techniques, such as multi-material printing, is being investigated. This integration could enable the creation of more complex and functional objects by combining glass with other materials.

– User-friendly systems: The development of user-friendly glass 3D printing systems is a key area of focus. User-friendly systems would make glass 3D printing more accessible and easier to use for a wider range of individuals and industries.

– Industry revolution: Glass 3D printing has the potential to revolutionize various industries, including architecture, design, and healthcare. The ability to create intricate and transparent designs opens up new possibilities for these industries, allowing for more innovative and unique products.

– Improved print speed and resolution: Advances in glass 3D printing technologies are aiming to improve print speed and resolution. This would enable faster production of glass objects with higher levels of detail and precision.

These potential advancements in glass 3D printing have the potential to reshape industries and unlock new opportunities for creativity and innovation. With ongoing research and development, the future of glass 3D printing looks promising.

Advantages of Using a Glass Print Bed

To fully reap the benefits of glass 3D printing, you should consider using a glass print bed, as it consistently provides a flat surface for your prints, ensuring excellent adhesion and allowing for effortless removal of finished prints. One of the advantages of using a glass print bed is its maintenance. Unlike other materials that require periodic replacement and recalibration, a glass bed only requires one-time setup. Additionally, glass is easy to clean, eliminating the need for promoters like glue or hairspray that require constant cleaning and reapplication.

Compatibility is another advantage of using a glass print bed. Glass remains flat and doesn’t deform under pressure, ensuring a level bed after each print job. This consistency is crucial for achieving accurate and high-quality prints. Furthermore, glass is highly compatible with different printing techniques, allowing for versatile applications.

When considering the cost, a glass print bed is a cost-efficient option. Glass is relatively low-priced compared to other materials, leading to less waste and requiring minimal maintenance. Additionally, glass is durable and rarely needs replacing, further reducing costs in the long run.

Tips for Getting the Best Results When Printing on Glass

To achieve optimal results when printing on a glass bed, follow these tips to ensure a smooth and successful printing experience:

– Glass printing techniques: Ensure that you are using the appropriate glass printing techniques for your specific printer model. Different printers may require different settings and configurations when printing on glass.

– Best glass bed adhesion methods: Experiment with different adhesion methods to find the one that works best for your prints. Glue stick and hairspray are popular options that provide good bed adhesion. Apply a thin, even layer of the adhesive to the glass bed before starting your print.

– Glass bed temperature recommendations: Adjusting the glass bed temperature can greatly affect the print quality. Start with a recommended bed temperature for the specific filament you are using and make small adjustments to find the optimal temperature for your prints.

– Troubleshooting glass printing issues: If you encounter issues such as warping or poor bed adhesion, try adjusting the bed temperature, reapplying the adhesive, or cleaning the glass bed thoroughly. Experimentation and troubleshooting are key to achieving the best results.

– Maintenance tips for glass print beds: Regularly clean the glass bed with soap and water or acetone to remove any dirt or residue that may affect adhesion. Inspect the glass bed for any scratches or damage and replace if necessary. Proper maintenance will ensure the longevity of your glass print bed and consistent print quality.

Tips for Cleaning a Glass Bed

When cleaning your glass bed, it is important to properly maintain and remove any dirt or residue that may affect adhesion. Cleaning techniques for a glass bed involve using specialized cleaning solutions and following maintenance tips to prevent scratches and remove stubborn residue. To clean your glass bed, start by removing any loose debris or particles with a soft brush or cloth. Next, you can use a specialized cleaning solution designed for glass surfaces to remove any stubborn residue. Apply the cleaning solution to a cloth and gently wipe the glass bed in a circular motion. Avoid using abrasive materials or harsh chemicals that may scratch or damage the surface. After cleaning, make sure to thoroughly dry the glass bed to prevent any water spots or streaks. Regularly cleaning your glass bed will ensure optimal adhesion and the longevity of your printing surface.

Advantages of Using Glue Stick and Hairspray for Adhesion

Using glue stick or hairspray for adhesion on a glass bed offers several advantages that can enhance your 3D printing experience.

Advantages of using glue stick for adhesion:

– Cheap and easy to apply

– Can be applied directly on the glass bed

– Excess glue can be washed off with water

– Provides good bed adhesion

– Can be used with high bed temperatures

Advantages of using hairspray for adhesion:

– Easily accessible and reliable

– Spray application method for even coating

– Adhesive power reactivates when heated

– Print removal is easier compared to glue stick

– Can be used with a wide range of bed temperatures

When it comes to alternative adhesion methods for 3D printing on glass, glue stick and hairspray have proven to be effective and convenient options. Compared to other adhesion techniques, such as using tape or specialty adhesion sheets, the advantages of using glue stick and hairspray are clear. They are cost-effective, easily accessible, and provide good bed adhesion. Additionally, both glue stick and hairspray can withstand high bed temperatures, making them suitable for a variety of printing materials. Whether you choose to use glue stick or hairspray, these adhesion methods offer reliable and consistent results, ensuring that your prints adhere securely to the glass bed throughout the printing process.