Are you fascinated by the world of art and creation? Have you ever wondered how artists are pushing the boundaries of design and customization? In this article, we’ll explore the exciting possibilities that 3D printing brings to the art world. With its ability to accurately render complex designs, 3D printing is revolutionizing industries like jewelry and fashion. But it doesn’t stop there. Artists are now embedding actuators, LEDs, and audio devices into their 3D printed art pieces, creating a new level of responsivity. Join us on this journey into the art of creation through the incredible world of 3D printing.

Pushing the Boundaries of Design

Push the boundaries of design with 3D printing technology, allowing you to create intricate and customized objects like never before. Design customization is one of the key advantages of 3D printing. With this technology, you can bring your unique vision to life with a level of intricate complexity that was previously unattainable. Whether you are a jewelry designer, fashion designer, or artist, 3D printing offers endless possibilities for creating highly detailed and personalized pieces.

Rapid prototyping is another area where 3D printing excels. It allows designers to quickly iterate and refine their designs, saving time and resources. This is particularly beneficial for interdisciplinary collaboration, where different experts from various fields can come together to create innovative and cutting-edge designs. For example, architects and computer scientists can collaborate on 3D printed art that combines architectural design with computing.

Historical preservation is also revolutionized by 3D printing. It enables the recreation of missing or damaged parts of historical artworks with remarkable accuracy and precision. The use of digital technologies ensures the preservation of important cultural artifacts for future generations.

Expanding Possibilities in Size and Complexity

With 3D printing technology, you can now explore new dimensions in size and complexity, taking your designs to unprecedented levels. This revolutionary technology has opened up a world of possibilities in various artistic fields. For jewelry designers, 3D printing allows for the creation of intricate and detailed designs that surpass the limitations of traditional handcrafting. Using SLA 3D printers, jewelry designers can capture extraordinary design details, giving them greater freedom and creativity. In the realm of installation art, 3D printing enables artists to create larger structures with intricate complexity. Artists like Philip Beesley can produce short runs of highly-customized pieces for their multidisciplinary art projects. Customized fashion accessories are also being revolutionized by 3D printing, as professional designers are able to create clothing accessories with precise details that were previously impossible. Additionally, 3D printing plays a significant role in historical art preservation, allowing for the recreation of missing or damaged parts of artworks with accurate details and textures. With 3D printing, the possibilities for size and complexity are expanding, pushing the boundaries of artistic creation.

Advancements in Prototyping and Production

To further enhance the capabilities of 3D printing technology, advancements in prototyping and production have revolutionized the way artists and designers bring their ideas to life. These advancements have made digital prototyping a cost-effective production method, especially for jewelers who can now create prototypes in-house using 3D printing technology. By utilizing digital workflows, artists are able to design, prototype, and produce large quantities of identical items with ease. The preservation of design is also made possible through 3D printing, as digitally stored designs can be accessed and iterated upon. Additionally, 3D printing technology allows for the scaling of complex parts, making it easier for artists to create intricate and detailed pieces.

To illustrate the impact of these advancements, consider the following table:

These advancements have not only transformed the way artists and designers work, but have also opened up new possibilities for creativity and innovation. With 3D printing, artists are no longer limited by traditional production methods and can now bring their ideas to life in ways that were once unimaginable.

Bridging Artistic Disciplines

By bridging artistic disciplines, you can explore the limitless possibilities of 3D printing technology. Interdisciplinary collaborations in the field of 3D printing have led to innovative applications and creative possibilities that were previously unimaginable. Technological advancements have enabled artists to express their creativity in new and exciting ways.

Artists from various fields, such as computer science, math, biology, architecture, and even fashion, are coming together to create unique and groundbreaking pieces using 3D printing. These collaborations result in the fusion of different artistic disciplines, pushing the boundaries of what is possible in art and design.

One example of this is the work of artists like Nervous System, who combine computer science, math, biology, and architecture to create unique art and housewares. Another example is the collaboration between Benjamin Dillenburger and Michael Hansmeyer, who combine architectural design and computing to create intricate 3D printed art.

The materials used in 3D printed art also vary widely, from resin to sandstone, allowing artists to experiment with different textures and finishes. This opens up a whole new world of possibilities for artistic expression.

Revolutionizing Art Restoration

Art restoration is being revolutionized by the use of 3D printing technology. This technology has brought significant advancements in the field of cultural heritage preservation and the conservation of fragile artifacts. One of the key applications of 3D printing in art restoration is the ability to replicate ancient sculptures with incredible precision. By utilizing 3D scanning technology, damaged or missing parts of artworks can be recreated, allowing for the restoration of these invaluable pieces.

The use of 3D printing in art restoration has enhanced conservation techniques by providing a more efficient and cost-effective process. The technology allows for the replication of intricate details and textures of original artworks, ensuring accuracy and preservation. By creating a digital model of the artwork, the 3D printer can precisely reproduce the object layer by layer, resulting in a faithful reproduction. This not only aids in the restoration process but also enables the study and analysis of the artwork without the risk of further damage.

The Digital Blueprint and Slicing the Object

When crafting objects through 3D printing, you begin the process with a digital blueprint and the slicing of the object into countless thin layers. The digital design process is crucial as it serves as a reference for the 3D printer to follow. Before printing, the 3D model is divided into these thin layers, similar to slicing a loaf of bread. Each slice represents a specific layer of the object, and this slicing process is essential for the layer-by-layer printing.

During the printing process, material selection is an important consideration. 3D printers can use a wide range of materials such as plastics, metals, ceramics, and even food. The choice of material depends on the object’s purpose and the printer’s capabilities. Different materials offer different properties and characteristics.

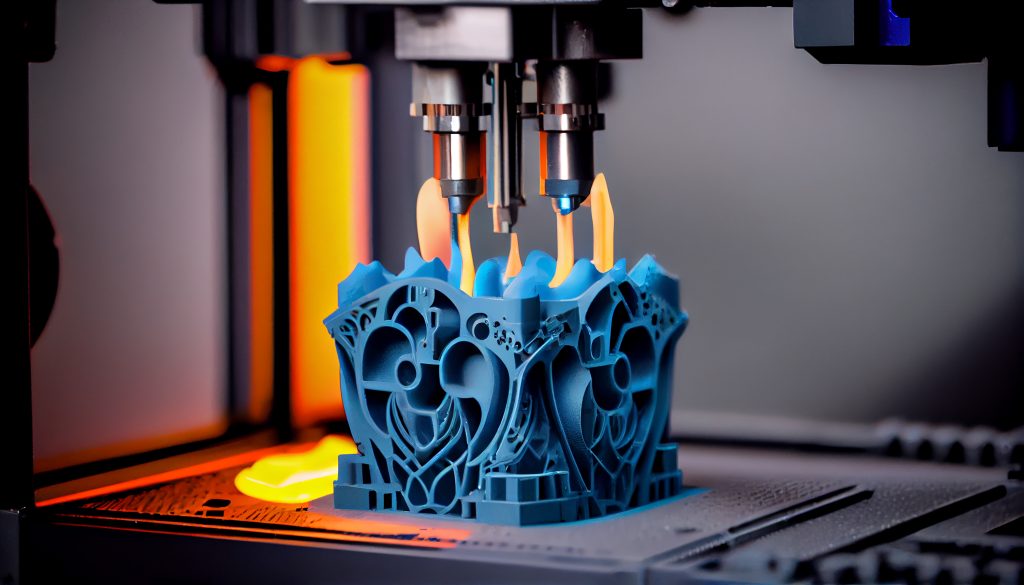

Once the material is selected, the printing process begins. The 3D printer’s print head or nozzle heats up the chosen material, transforming it into a semi-liquid state. The nozzle then moves precisely according to the digital design, depositing the material layer by layer to form the object. Accuracy and precision are crucial during the printing process.

As each layer is deposited, it quickly cools and solidifies. Some printers use lasers or UV light to harden certain materials. The solidified layers bond together, ensuring structural integrity and stability of the final object.

Printing Material and The Printing Process

To continue the discussion on crafting objects through 3D printing, let’s delve into the printing material and the process itself. 3D printers use a wide range of materials, including plastics, metals, ceramics, and even food. The choice of material depends on the object’s purpose and the printer’s capabilities. Different materials offer different properties and characteristics, allowing for a variety of 3D printing applications.

Choosing the right material is crucial for achieving the desired outcome. Plastics like ABS are commonly used for their sturdiness and versatility, making them suitable for small objects like nuts, bolts, and action figures. Other materials, such as wax, resin, ceramic, and nylon, offer unique features and can be used for specific applications.

The printing process starts with the print head or nozzle heating up the chosen material, transforming it into a semi-liquid state. The nozzle then moves precisely according to the digital design, depositing the material layer by layer to form the object. Accuracy and precision are essential during this process.

Once each layer is deposited, it quickly cools and solidifies, and in some cases, lasers or UV light are used to harden certain materials. The solidified layers bond together, ensuring the structural integrity and stability of the final product.

Post-processing techniques can be applied to enhance the appearance and functionality of 3D printed objects, such as sanding, painting, or adding additional components.

In the realm of industrial 3D printing, advancements are continuously being made to improve the printing process, materials, and capabilities. Future developments may include the introduction of new materials with enhanced properties, faster printing speeds, and improved accuracy.

Solidification and Bonding

Solidification and bonding are crucial steps in the 3D printing process that ensure the structural integrity and stability of the final object. These steps are essential for achieving high-quality prints with strong and durable properties. Here are some key aspects of solidification and bonding in 3D printing:

– Solidification techniques: Different 3D printing technologies employ various solidification techniques. Some printers use lasers or UV light to rapidly cool and harden the deposited material layers. This ensures quick solidification and bonding between layers.

– Bonding methods: The bonding between layers can be achieved through various methods, such as heat, pressure, or chemical reactions. These methods promote the fusion of adjacent layers, enhancing the overall strength and stability of the printed object.

– Structural integrity: Solidification and bonding play a crucial role in maintaining the structural integrity of the printed object. They help prevent layer separation and ensure that the final product can withstand external forces and maintain its shape over time.

– Material properties: The choice of materials used in 3D printing can affect the solidification and bonding process. Each material has its own unique properties, such as melting point and viscosity, which influence the solidification time and bonding strength.

– Print quality: The solidification and bonding process directly impact the overall print quality. Proper solidification and strong bonding between layers result in smooth surfaces, minimal defects, and accurate dimensions, contributing to a high-quality final object.

Materials Used in 3D Printing

When it comes to 3D printing, a wide range of materials can be used, including plastic, powders, resins, metal, and even carbon fiber. Each material offers unique properties and characteristics that make it suitable for different purposes. The choice of material depends on factors such as the object’s intended use, the printer’s capabilities, and the desired outcome. Understanding the materials used in 3D printing is essential for achieving accurate and high-quality prints.

Plastic

Using a wide range of materials, one of the most common materials utilized in 3D printing is ABS plastic. ABS plastic is generally very strong, with the strength depending on the dimensions of the print. Thicker objects tend to be stronger than thin ones. Additionally, flexible plastic pieces can also be printed, allowing for more versatility in design. When designing a print, it is important to consider the intended use and weight distribution to ensure the strength of the final product. In terms of finding 3D models for printing, there are various resources available, such as Thingaverse, which offers a free 3D model library. Other options include using services like Mineways and Shapeways for 3D modeling and printing Minecraft models. If you are looking to get a 3D printer, there are many options available, with recognized brands like Makerbot and Solidoodle offering for-sale printers. The Makerbot Replicator, for example, provides a large print area, two-color printing, and a convenient LCD user interface. Finally, understanding how a 3D printer works is important. The process involves feeding plastic filament through a heating mechanism and nozzle, melting the plastic, and then moving a platform in three dimensions to form the object. The nozzle traces the outline of the model and fills in the middle with crisscross patterns of plastic strands, which solidify and bond together to form a solid body.

Powders

Exploring the versatility of 3D printing, you can create objects using various powders as the material. Powders, such as metals, ceramics, and plastics, offer unique applications and advantages in the 3D printing process. Metal powders, like titanium and aluminum, are commonly used for industrial applications due to their strength and durability. Ceramic powders, such as porcelain, enable the creation of intricate and delicate objects like jewelry and decorative pieces. Plastic powders, like nylon and polyamide, are ideal for producing functional prototypes and consumer products. However, working with powders in 3D printing presents challenges, such as powder handling and post-processing requirements. The future prospects for powders in 3D printing include advancements in material development, improved printing techniques, and expanded applications in various industries.

Resins

To understand the role of resins in 3D printing, you need to know that they are commonly used as the primary material for creating objects. Resins come in various types, each with its own unique properties and applications. Some common resin types used in 3D printing include photopolymer resins, thermoplastic resins, and castable resins. Photopolymer resins are popular for their ability to cure quickly when exposed to UV light, making them suitable for creating highly detailed objects. Thermoplastic resins, on the other hand, offer durability and strength, making them ideal for functional parts. Castable resins are used in jewelry making, as they can be burned out to create metal objects. When working with resins, it is important to follow safety precautions, such as wearing gloves and working in a well-ventilated area, as some resins may emit fumes during the curing process.

Metal

When working with resins in 3D printing, it is important to follow safety precautions and consider the unique properties and applications of different resin types. Now, let’s delve into the world of metal 3D printing. Metal 3D printing offers numerous benefits and has a wide range of applications. It allows for the creation of complex geometries, intricate designs, and functional metal parts. However, metal 3D printing also presents its fair share of challenges, such as high costs, limited material options, and the need for post-processing. Despite these challenges, there have been significant advances in metal 3D printing technology, including improved printing speed, increased material options, and enhanced precision. The future of metal 3D printing looks promising, with ongoing research and development focused on improving the process and expanding its applications in various industries.

Carbon fiber

Now, let’s delve into the world of carbon fiber, a popular material used in 3D printing, to further expand our understanding of the materials used in this innovative technology.

– Carbon fiber has a wide range of applications in 3D printing, including aerospace, automotive, and sports industries.

– Carbon fiber is known for its exceptional strength-to-weight ratio, making it ideal for creating lightweight yet strong objects.

– Carbon fiber composites, which combine carbon fibers with other materials like resin, enhance the strength and durability of 3D printed objects.

– Carbon fiber manufacturing involves the process of weaving carbon fibers into a fabric-like structure before they are infused with resin and cured.

– Carbon fiber properties, such as high stiffness, low thermal expansion, and resistance to corrosion, make it a versatile material for various applications in 3D printing.

How a 3D Printer Works

How does a 3D printer work? The process of 3D printing involves filament melting, layer deposition, solidification techniques, and printing precision. The journey begins with a digital 3D model or blueprint, serving as a guide for the printer. The model is divided into countless thin layers, similar to slicing a loaf of bread. Each layer represents a specific layer of the object and is essential for the layer-by-layer printing. 3D printers use a wide range of materials, such as plastics, metals, ceramics, and even food. The chosen material is heated by the print head or nozzle, transforming it into a semi-liquid state. The nozzle moves precisely according to the digital design, depositing the material layer by layer to form the object. As each layer is deposited, it quickly cools and solidifies, bonding together to create the final object. The solidification and bonding process is crucial for the object’s structural integrity and stability. Through this intricate process, 3D printers achieve printing precision, allowing for the creation of highly detailed and accurate objects.