In this guide, you’ll discover the wonders of stereolithography (SLA) 3D printing. With SLA, you can create high-resolution, accurate, and beautifully smooth parts. Whether you’re in engineering, product design, dental, or jewelry industries, SLA has got you covered.

Learn how to design your models, optimize printing settings, and post-process your prints for the best results. With the introduction of low force stereolithography (LFS) technology, SLA is taking it to the next level.

Get ready to experience fine features, smooth finishes, and unparalleled precision. Let’s dive in!

SLA 3D Printing Service

If you’re looking for a reliable SLA 3D printing service, our Vipers, ProJets, and iPros are equipped to handle your needs with their high-resolution mode and large build volumes.

Our SLA 3D printing materials are carefully selected to ensure high-quality and accurate prints.

When comparing SLA to other 3D printing technologies, SLA stands out for its ability to produce parts with small features, tight tolerance requirements, and smooth surface finishes.

By outsourcing your SLA printing needs to us, you can benefit from cost savings, as well as access to state-of-the-art equipment and expertise.

Our team of experts will ensure that your projects are completed efficiently and to your satisfaction.

Trust us with your SLA 3D printing needs and experience the advantages of outsourcing.

SLA Design Guidelines and Capabilities

SLA design guidelines outline the capabilities and considerations for creating successful 3D prints. When designing for SLA, it is important to take into account the unique characteristics of the process.

SLA has the capability to produce parts with high resolution, accuracy, and smooth surface finishes. However, there are also limitations to be aware of, such as the need for support structures and the potential for curling and layer adhesion issues.

To ensure successful prints, it is recommended to follow design guidelines that address these considerations. This includes properly orienting the part, designing adequate support structures, and considering the post-curing process.

SLA Material Options

When choosing materials for your 3D prints, you have a variety of options available in SLA technology. SLA material options include resin selection, which is crucial in determining the properties of your printed parts.

Different resins have different material properties, such as strength, flexibility, and heat resistance. It is important to consider the specific requirements of your project when choosing the right material.

For example, if you need a durable and rigid part, a standard resin would be suitable. On the other hand, if you require a flexible and impact-resistant part, a flexible resin would be a better choice.

Comparison of SLA Material Properties

To choose the right material for your 3D prints, compare the properties of different SLA materials available. When comparing SLA material properties, consider the benefits and challenges of SLA 3D printing.

SLA offers high accuracy, smooth surface finishes, and the ability to match the properties of standard, engineering, and industrial thermoplastics. These benefits make SLA suitable for producing high-accuracy prototypes and end-use parts in various industries.

However, SLA printing also comes with challenges such as curling, layer adhesion, and the need for post-curing. It’s important to consider these challenges and find ways to mitigate them in your printing process.

Our SLA 3D Printers

Our Vipers, ProJets, and iPros are our stereolithography machines. They can produce high-resolution parts with tiny features and crisp details.

SLA 3D printing offers several advantages compared to other 3D printing technologies. One advantage is the ability to create parts with fine features and a smooth surface finish.

SLA also provides ultimate part precision and accuracy, making it preferred by engineers, designers, and manufacturers. The versatility of SLA materials allows for the production of parts with various mechanical attributes, such as isotropy and watertightness.

These advantages make SLA 3D printing suitable for a wide range of applications in industries such as engineering, product design, dental, and jewelry.

With our SLA printers, you can achieve high-quality parts that meet your specific requirements.

Vipers, Projets, and Ipros Are Our Stereolithography Machines

Vipers, ProJets, and iPros are our stereolithography machines, offering high-resolution parts with fine details and a smooth surface finish.

The Viper 3D Printer, in particular, has several advantages. It can produce parts with tiny features and crisp details in high-resolution mode. Additionally, it can build cost-effective parts quickly in normal-resolution mode.

When comparing SLA and FDM printing, SLA has the benefits of producing parts with small features, tight tolerance requirements, and smooth surface finishes. This makes SLA ideal for prototyping.

Using SLA for prototyping has several benefits, including the ability to deliver complex prototypes quickly and accurately, improving product development.

With our Viper 3D Printer, you can take advantage of these benefits and create high-quality prototypes with ease.

Vipers and Projets Can Produce Parts With Tiny Features and Crisp Details in High-Resolution Mode

With the Viper 3D Printer, you’ll be amazed at how tiny features and crisp details can be achieved in high-resolution mode. The advantages of high resolution SLA printing are evident in the ability to produce parts with exceptional precision and clarity.

To achieve crisp details in SLA prints, techniques such as layer thickness adjustment and proper support structure placement are utilized. The Viper, along with the ProJet, excels in high resolution mode, delivering stunning results.

The Viper offers a build volume of 10 in. by 10 in. by 16 in., allowing for the creation of larger parts without sacrificing detail. Both printers ensure that intricate designs and fine details are accurately reproduced, making them ideal for applications in industries such as engineering, product design, and jewelry making.

Vipers and Projets Can Build Cost-Effective Parts Quickly in Normal-Resolution Mode

You can build cost-effective parts quickly in normal-resolution mode using the Vipers and ProJets.

In normal resolution mode, these 3D printers offer a balance between speed and quality, allowing you to produce parts efficiently without compromising on accuracy.

The benefits of normal resolution mode include shorter print times and reduced material consumption, resulting in cost savings.

While high-resolution mode is ideal for intricate designs and fine details, normal resolution mode is perfect for projects that prioritize speed and cost-effectiveness.

By comparing normal resolution mode with high resolution mode, you can determine the most suitable option based on your specific needs and budget.

Whether you require highly detailed parts or quick turnaround times, the Vipers and ProJets in normal resolution mode can meet your requirements efficiently.

Ipros Have Large Build Volumes of 29 In. by 25 In. by 21 in

The iPros have a spacious build volume of 29 in. by 25 in. by 21 in., allowing for the creation of large and highly detailed parts. This advantage makes the iPros ideal for various industries that require the production of big and intricate objects.

With its generous build size, the iPros can accommodate the printing of large-scale prototypes, architectural models, and functional parts. Compared to other SLA printers, the iPros stand out with their ability to handle bigger projects without compromising on detail and precision.

Whether it’s in the engineering, automotive, or even medical field, the iPros offer a reliable solution for creating complex components with exceptional accuracy. The applications of iPros in various industries are vast, making them a valuable asset for businesses looking to leverage the benefits of SLA 3D printing.

Ipros Can Easily Create Highly Detailed Parts

The iPros have several advantages that make them a valuable tool for industries that require highly intricate components. They can effortlessly produce parts with exceptional detail and precision. The high-resolution capabilities of these machines allow for the production of intricate designs and complex geometries. They also have a large build volume, which enables the creation of larger parts or multiple parts in a single build.

However, it is important to note that iPros also have some limitations. The large build volume can result in longer print times and higher material costs. Additionally, the high level of detail and precision achieved by iPros may require additional post-processing steps to remove support structures and achieve the desired surface finish.

Despite these limitations, the applications of iPros are vast. They are commonly used in industries such as aerospace, automotive, medical, and jewelry. In these industries, highly detailed and precise components are essential for successful manufacturing processes.

Why Use SLA

SLA is a suitable additive manufacturing process for prototyping and production due to its ability to 3D print parts with small features, tight tolerance requirements, and smooth surface finishes.

The advantages of SLA 3D printing are numerous. It offers fine features and smooth surface finish, providing ultimate part precision and accuracy. SLA also offers isotropy, watertightness, and material versatility, making it preferred by engineers, designers, and manufacturers.

The benefits and applications of SLA 3D printing are vast. It is popular for producing high-accuracy, isotropic, and watertight prototypes and end-use parts. SLA parts have sharp details and smooth surface finishes, and SLA resins can match the properties of standard, engineering, and industrial thermoplastics.

The next chapter of SLA is Low Force Stereolithography (LFS) 3D printing. LFS technology reduces forces exerted on parts during the print process, resulting in improved surface quality and print accuracy. With LFS, light-touch support structures are possible, opening up possibilities for future development of advanced materials.

SLA Can 3D Print Parts With Small Features, Tight Tolerance Requirements, and Smooth Surface Finishes

SLA can achieve high precision and smooth finishes for 3D printed parts with small features and tight tolerance requirements.

The benefits of SLA 3D printing are numerous. It allows for the production of high-accuracy, isotropic, and watertight prototypes and end-use parts. SLA parts have sharp details and smooth surface finishes, making them ideal for various applications.

The SLA 3D printing workflow involves designing the model using CAD software or 3D scan data, exporting it in a 3D printable file format, specifying printing settings, and slicing the model into layers.

After the printing process, the printed parts undergo post-processing, including rinsing, post-curing, and removing supports if necessary.

SLA 3D printing finds applications in engineering, product design, dental, and jewelry industries, helping professionals optimize production processes and cut outsourcing costs.

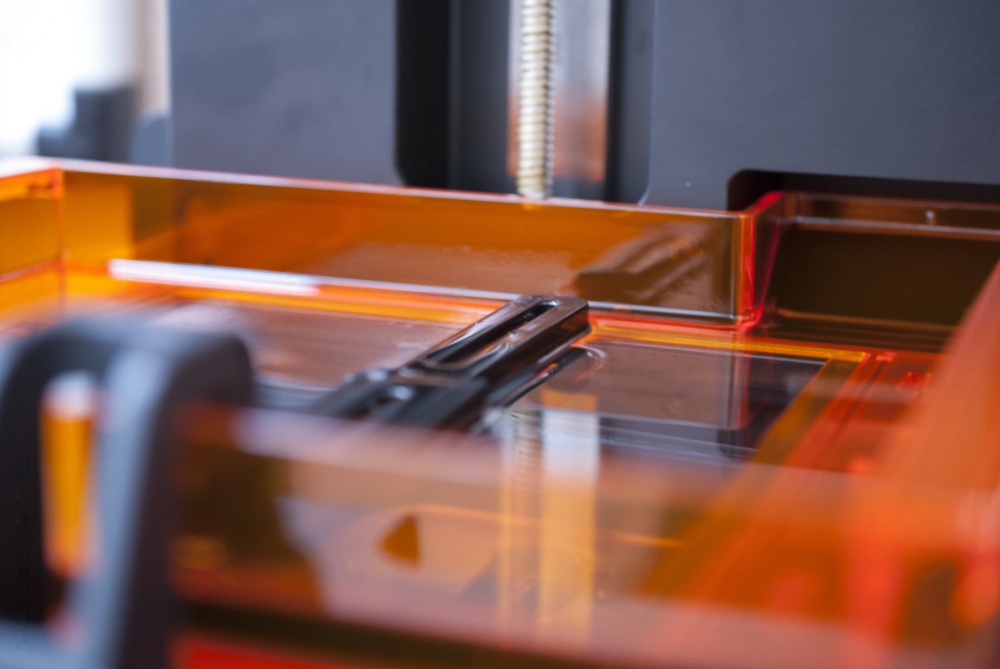

SLA Is an Additive Manufacturing Process

To understand how SLA works, you can visualize the process of using an ultraviolet laser on the surface of a liquid thermoset resin to build layers and create a 3D printed part.

SLA 3D printing offers several advantages. It can produce parts with fine features and smooth surface finishes, providing ultimate precision and accuracy. SLA also offers isotropy, watertightness, and material versatility, making it a preferred choice for engineers, designers, and manufacturers.

However, there are challenges in SLA 3D printing. Curling, caused by resin shrinkage and internal stresses, is a common issue. Layer adhesion and post-curing are also considerations for the strength and properties of SLA parts.

Additionally, there are differences between desktop and industrial SLA printers. Industrial printers offer higher accuracy, larger build sizes, and a wider range of materials, while desktop printers are more suitable for cosmetic appearance.

SLA Is Suitable for Prototyping and Production

When considering your manufacturing needs, you’ll find that SLA is a suitable option for both prototyping and production.

The benefits of using SLA for prototyping and production are numerous. SLA 3D printing offers fine features, smooth surface finish, and ultimate part precision and accuracy. It also provides isotropy, watertightness, and material versatility.

Compared to other 3D printing technologies, SLA has distinct advantages for rapid prototyping. Additionally, SLA is cost-effective for small-scale manufacturing, making it an ideal choice for businesses looking to optimize their production processes.

With SLA, you can quickly and accurately create complex prototypes, improve product development, and cut outsourcing costs. So, whether you’re in the prototyping phase or ready for full-scale production, SLA is the way to go.

SLA Can Deliver Complex Prototypes Quickly and Accurately

If you need to create complex prototypes quickly and accurately, you can rely on SLA technology. SLA 3D printing offers a range of benefits for rapid prototyping.

Compared to other technologies like FDM, SLA provides high accuracy, fine details, and smooth surface finishes. With advancements in SLA technology, the process has become more accessible and versatile. SLA printers can produce parts with small features and tight tolerance requirements, making them suitable for creating intricate prototypes.

The speed and precision of SLA allow for efficient product development, helping professionals cut outsourcing costs and optimize production processes. Whether you’re in engineering, product design, dental, or jewelry, SLA 3D printing can deliver complex prototypes quickly and accurately, making it a valuable tool for rapid prototyping.

SLA Can Improve Product Development

By utilizing SLA technology, you can enhance your product development process. SLA 3D printing offers numerous benefits for product development, making it a preferred choice over other 3D printing technologies.

With SLA, you can create high-accuracy and watertight prototypes and end-use parts with sharp details and smooth surface finishes. SLA resins can match the properties of standard, engineering, and industrial thermoplastics, providing material versatility for your projects.

This technology allows professionals in industries such as engineering, product design, dental, and jewelry to optimize their production processes and cut outsourcing costs.

How Does SLA 3D Printing Work

Now that you understand how SLA can improve product development, let’s dive into how SLA 3D printing actually works.

In SLA 3D printing, the working principles involve positioning the build platform in a tank of liquid photopolymer. A UV laser is used to selectively cure and solidify the photopolymer resin, creating each layer of the desired object. Galvos are used to focus the laser beam and scan the entire cross-sectional area of the model. After printing, the part undergoes post-processing under UV light to fully cure it.

SLA 3D printing utilizes a variety of materials with different characteristics. Support structures are always required in SLA and need to be manually removed after printing. Curling, caused by resin shrinkage and internal stresses, is a common challenge in SLA printing. Layer adhesion is crucial for the strength and integrity of SLA parts. Post-curing can improve the properties of SLA parts but may also make them more brittle. Additionally, extended exposure to UV light can negatively affect the physical properties and appearance of SLA parts.

Overall, understanding the working principles, materials, and challenges of SLA 3D printing is essential for successful implementation and production.

SLA Uses an Ultraviolet Laser on the Surface of a Liquid Thermoset Resin

The ultraviolet laser in SLA 3D printing cures a liquid thermoset resin on the surface to create each layer of the object. This UV laser technology offers several advantages.

First, it provides fine features and a smooth surface finish, resulting in high-quality prints.

Second, the selection of the right resin is crucial for achieving desired properties and characteristics in the final part. Different resins offer different mechanical, thermal, and chemical properties, allowing for material versatility.

Lastly, post-processing techniques play a significant role in enhancing SLA parts. Techniques such as rinsing in isopropyl alcohol, post-curing, removing supports, and sanding can improve the overall appearance and performance of the printed parts.