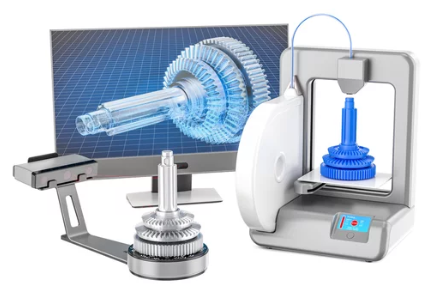

Are you curious about the cutting-edge developments in material science and the transformative impact they have on the realm of 3D printing? If you are, then this article on ‘Innovation in Material Science: 3D Printing With UHMWPE’ is tailored to your interests. Here, we explore the limitless possibilities that arise when combining the prowess of 3D printing with Ultra-High Molecular Weight Polyethylene (UHMWPE) – a cost-effective and environmentally sustainable material. Join us in unraveling how this groundbreaking substance is reshaping the future of manufacturing.

Advantages of 3D Printing With UHMWPE

When 3D printing with UHMWPE, you can benefit from its numerous advantages. UHMWPE, or Ultra-High Molecular Weight Polyethylene, possesses exceptional material properties that make it an ideal choice for additive manufacturing. One of its key advantages is its high strength-to-weight ratio, which allows for the production of lightweight yet durable parts. Additionally, UHMWPE has excellent chemical resistance, making it suitable for applications in harsh environments.

Another advantage of 3D printing with UHMWPE is its manufacturing efficiency. UHMWPE has low friction properties, which enables smooth and easy printing, reducing the risk of clogs or jams. Its high viscosity also contributes to better layer adhesion and dimensional stability during the printing process.

Cost effectiveness is also a significant advantage of 3D printing with UHMWPE. Compared to traditional manufacturing methods, 3D printing with UHMWPE requires less material waste, leading to cost savings. Moreover, the ability to create complex geometries and customized designs eliminates the need for costly tooling or molds.

Looking towards the future, there are exciting developments in UHMWPE 3D printing. Researchers are exploring ways to enhance UHMWPE’s mechanical properties and expand its range of applications. With ongoing advancements, the potential for UHMWPE in additive manufacturing is vast.

Applications in Medical Field

3D printing with UHMWPE offers numerous applications in the medical field, providing a wide range of possibilities for personalized and cost-effective healthcare solutions. This innovative technology is being used in various areas of medicine, including orthopedic devices, organ printing, medical device spare parts, 3D printed PPE (personal protective equipment), and affordable prosthetic limbs.

Orthopedic devices, such as hip and knee replacements, can be 3D-printed using UHMWPE, reducing production time and costs while improving patient outcomes. Additionally, 3D printing is progressing to the point of creating human organs, potentially eliminating the need for organ donors and revolutionizing the field of transplantation.

Furthermore, 3D printing can be utilized to create spare parts for medical devices, improving accessibility and reducing costs. This is particularly crucial in situations where specific parts may be difficult to obtain or expensive to produce using traditional manufacturing methods.

During times of crisis, 3D printing can play a vital role in producing essential medical supplies, including PPE, such as masks, ensuring their availability and reducing dependence on external suppliers.

Lastly, 3D printing allows for the production of affordable prosthetic limbs for both humans and pets, making healthcare more accessible and improving the quality of life for individuals in need.

The table below provides a concise overview of the applications of 3D printing with UHMWPE in the medical field:

| Applications | Description |

|---|---|

| Orthopedic devices | 3D printing allows for the production of personalized and cost-effective implants |

| Organ printing | Potential to create human organs, reducing the need for organ donors |

| Medical device spare parts | Enables the creation of spare parts for medical devices |

| 3D printed PPE | Production of essential medical supplies, such as masks |

| Affordable prosthetic limbs | 3D printing enables the production of cost-effective prosthetic limbs |

Industrial Uses of UHMWPE 3D Printing

To fully explore the potential of UHMWPE 3D printing in industrial applications, consider the wide range of possibilities in improving manufacturing processes and reducing costs. With its unique properties, UHMWPE offers several advantages for cost-effective manufacturing and industrial efficiency. Here are some key points to consider:

– Material Compatibility:

– UHMWPE is compatible with a variety of other materials, allowing for the creation of multi-material components and enhancing the functionality of printed parts.

– Its excellent adhesion properties ensure strong bonding between layers, resulting in durable and reliable printed objects.

– Durability Testing:

– UHMWPE’s exceptional mechanical properties, such as high impact strength and wear resistance, make it ideal for durability testing of prototypes and functional parts.

– By 3D printing UHMWPE components, manufacturers can assess their performance under real-world conditions, ensuring high-quality end products.

– Production Scalability:

– UHMWPE 3D printing enables the production of complex geometries and intricate designs with ease, allowing for innovative solutions in various industries.

– Its ability to quickly fabricate parts reduces lead times and enables on-demand manufacturing, improving overall production scalability.

Consumer Applications and DIY Projects

Now, let’s delve into how you can leverage UHMWPE 3D printing for consumer applications and DIY projects, taking advantage of its unique properties and versatility. UHMWPE, with its high strength, low friction, and excellent wear resistance, is well-suited for a range of residential applications. With UHMWPE 3D printing, you can create custom parts for home repair and improvement projects, ensuring a perfect fit and reducing the need for costly replacements. Additionally, UHMWPE’s durability makes it ideal for creating water features in residential settings, allowing you to design and construct unique and customizable fountains, ponds, and waterfalls.

Beyond residential applications, UHMWPE 3D printing opens up possibilities for artistic creations. Artists and crafters can utilize this technology to bring their designs to life, producing intricate and detailed sculptures, decorative objects, and jewelry. The versatility of UHMWPE allows for a wide range of creative possibilities, enabling artists to experiment with different shapes, textures, and finishes.

Moreover, UHMWPE 3D printing enables collaboration within networks of like-minded individuals. By sharing designs and collaborating on projects, enthusiasts can collectively build larger and more complex use cases for 3D printing at home. This collaborative approach not only fosters creativity and innovation but also creates opportunities for revenue generation. Work-from-home creators can leverage UHMWPE 3D printing to produce and sell customized products, tapping into niche markets and generating income from their creative endeavors.

Architectural and Urban Planning Possibilities

Explore the architectural and urban planning potential of UHMWPE 3D printing. With its ability to create intricate and complex structures, UHMWPE 3D printing offers a range of possibilities for urban development and sustainable design.

– Architectural Models: UHMWPE 3D printing enables the creation of highly detailed architectural models. These models provide tangible artifacts that allow people to better relate to proposed spaces. The use of 3D printed models can revolutionize the visualization and communication of architectural designs.

– Community Engagement: By utilizing UHMWPE 3D printing, urban planners can engage the community in the planning process. The creation of 3D printed models allows for greater community involvement and understanding of proposed developments. This engagement can lead to more inclusive and sustainable design solutions.

– Urban Revitalization: UHMWPE 3D printing presents opportunities for urban revitalization. By using this technology, urban planners can address issues such as housing shortages and homelessness. The ability to quickly and cost-effectively produce architectural components and structures can contribute to the revitalization of urban areas.

Incorporating UHMWPE 3D printing into architectural and urban planning processes offers a new level of precision, efficiency, and sustainability. It allows for the creation of detailed architectural models, enhances community engagement, and contributes to urban revitalization efforts. As the technology continues to advance, the possibilities for utilizing UHMWPE 3D printing in the field of architecture and urban planning are vast, promising a future of innovative and sustainable design solutions.

3D Printing in Space Exploration

As you delve into the realm of 3D printing in space exploration, consider the immense potential it holds for delivering supplies, parts, and components to the Space Station without the need for costly manned space operations. 3D printing in space habitats opens up new possibilities for sustaining long-duration missions and reducing dependence on Earth for resupply. Additionally, 3D printing for lunar exploration and Mars colonization offers the ability to create essential infrastructure and repair critical equipment on-site, reducing the need for extensive logistics and minimizing the risk associated with transporting materials from Earth.

However, there are unique challenges to overcome when it comes to 3D printing in zero gravity environments. The absence of gravity affects the behavior of molten materials, making it difficult to maintain precise control over the printing process. Furthermore, the lack of a stable surface can pose challenges in ensuring the adhesion and structural integrity of printed objects.

Despite these challenges, the future of 3D printing in space technology looks promising. Researchers and engineers are actively working on developing new printing techniques and materials that are specifically designed for use in space. This includes the exploration of alternative printing methods, such as using lasers or electron beams to melt and solidify materials in microgravity conditions.

Educational Benefits and Training Opportunities

3D printing in education offers students a transformative learning experience, empowering them to actively engage in designing, prototyping, and acquiring practical skills through the use of 3D models. This innovative technology not only benefits students but also provides training opportunities for educators to enhance their teaching methods. Here are some key points to consider:

– Training opportunities for educators:

– Educators can attend workshops and training sessions to learn how to integrate 3D printing in their curriculum effectively.

– They can gain knowledge about the latest advancements in 3D printing technology and its applications in various industries.

– Integrating 3D printing in curriculum:

– Educators can incorporate 3D printing into STEM subjects, allowing students to explore concepts through hands-on learning.

– By integrating 3D printing, educators can enhance problem-solving skills, critical thinking, and creativity among students.

– Benefits of hands-on learning with 3D printing:

– Students can actively participate in the learning process by designing and prototyping their ideas using 3D printing technology.

– Hands-on learning with 3D printing enables students to develop practical skills and gain a deeper understanding of complex concepts.

– Collaborative projects using 3D printing technology:

– Students can work together on collaborative projects, fostering teamwork and communication skills.

– Collaborative projects using 3D printing technology encourage students to share ideas, collaborate, and solve problems collectively.

– Future career prospects in the 3D printing industry:

– By incorporating 3D printing in education, students can gain valuable skills and knowledge that can lead to future career opportunities in the growing 3D printing industry.

– The demand for professionals with expertise in 3D printing technology is increasing in various fields such as engineering, manufacturing, healthcare, and architecture.

Testing and Prototyping Advancements

To advance testing and prototyping processes, incorporate 3D printing with UHMWPE fibers and PLA matrix in the ME3DP process. This combination offers several benefits in terms of material compatibility and testing parameters. UHMWPE fibers are known for their high strength and durability, making them suitable for testing and prototyping applications. By integrating these fibers with a PLA matrix, the resulting composite material exhibits improved mechanical properties and enhanced performance.

Advancements in testing technology have also contributed to the progress of testing and prototyping processes. With the use of 3D printing, it is now possible to create complex geometries and intricate designs, allowing for more accurate and realistic prototypes. Additionally, digital twin technology enables the creation of virtual prototypes for testing and simulation purposes, reducing the need for physical prototypes.

However, there are potential limitations and challenges when it comes to testing and prototyping with UHMWPE and PLA. For example, optimizing the printing parameters and settings to achieve the desired mechanical properties can be a complex task. Furthermore, the adhesion between the UHMWPE fibers and PLA matrix needs to be carefully controlled to ensure the integrity of the final prototype.

Environmental Impact and Sustainability

Reducing waste and promoting sustainability, 3D printing with UHMWPE contributes to a more environmentally friendly approach to manufacturing. This innovative technology offers several benefits in terms of environmental impact and sustainability, including:

– Environmental sustainability:

– 3D printing with UHMWPE allows for the use of environmentally friendly materials, reducing the strain on natural resources and minimizing the carbon footprint of the manufacturing process.

– The ability to create custom parts using 3D printing reduces the need for mass production and excessive waste generated by traditional manufacturing methods.

– Economic viability:

– 3D printing with UHMWPE offers cost-effective solutions, as it eliminates the need for molds and reduces material waste.

– By streamlining the production process and minimizing material usage, 3D printing with UHMWPE can lead to significant cost savings in the long run.

– Material compatibility:

– UHMWPE is a highly compatible material for 3D printing, allowing for the production of durable and high-quality parts.

– Its excellent mechanical properties, such as high impact strength and low friction, make UHMWPE suitable for a wide range of applications.

– Manufacturing efficiency:

– 3D printing with UHMWPE enables rapid prototyping and on-demand production, reducing lead times and improving overall manufacturing efficiency.

– The ability to produce complex geometries and intricate designs with ease enhances the design freedom and flexibility of the manufacturing process.

– Waste reduction:

– 3D printing with UHMWPE minimizes material waste by only using the exact amount of material required for production.

– The ability to recycle and reuse UHMWPE materials further reduces waste and contributes to a more sustainable manufacturing process.

Niche Solutions and Customized Products

For niche markets and specialized needs, 3D printing with UHMWPE offers the ability to create unique and customized products. This innovative technology allows for customized manufacturing, making it possible to produce products that are tailored to individual requirements. With 3D printing, emerging markets now have access to creative applications and unique designs that were previously limited to larger industries. The versatility of UHMWPE in 3D printing opens up a world of possibilities for niche solutions.

Whether it’s developing custom parts, creating personalized prototypes, or manufacturing one-of-a-kind products, 3D printing with UHMWPE provides the flexibility and precision needed to meet specific demands. This technology is revolutionizing the way products are designed and manufactured, enabling businesses to offer specialized solutions to their customers. By embracing 3D printing with UHMWPE, companies can differentiate themselves in the market and cater to the unique needs of their customers. It’s an exciting time for customized manufacturing, as 3D printing with UHMWPE continues to push the boundaries of innovation and customization.