Have you ever wondered if you can print in 3D upside down? Well, you’re in luck! In this article, we’ll explore the concept of upside-down 3D printing and its implications. We’ll discuss the benefits of this unconventional printing method, such as increased portability and simplicity. We’ll also dive into the results of an experiment conducted by Angus from Makers Muse, who tested different printing orientations. So, join us as we uncover the potential of upside-down 3D printing for creativity and innovation.

Background of Upside-Down Printing

How does upside-down printing work and what is its background? Upside-down printing, a technique used in 3D printing, has gained popularity among Reprap User Groups (RUGs) and has been explored by various communities and organizations. One such group is the Portuguese RUG, which focuses on the development of RepRap technology in Portugal and Brazil. The RUG has a separate forum dedicated to discussions in Portuguese and has highlighted the significance of Darwin as the first RepRap.

Another notable organization is the RepLab Working Group, which aims to create self-replicating Fab Labs. Their research and development efforts have contributed to the advancement of upside-down printing techniques. Additionally, the Kartik M. Gada Humanitarian Innovation Prize recognizes innovative ideas and projects in the field of 3D printing. The forum information reveals that the Reprap Forum, powered by Phorum, serves as a platform for designer and engineer participation. By exploring these various groups and initiatives, we can gain a deeper understanding of the background and significance of upside-down printing in the 3D printing community.

Printing Orientation and Its Impact

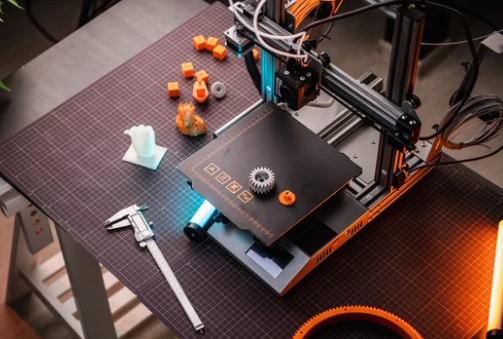

In the article ‘Is Upside-Down 3D Printing Possible?’, let’s delve into the subtopic of printing orientation and its impact. When it comes to 3D printing, the orientation of the printer does not significantly affect the printing process. Experienced 3D printer users know that FDM printers work fine upside down or right side up, and 3D printing can even be done in zero gravity. In fact, flipping an existing 3D printer on its side or upside down works just fine. However, printing upside down does offer some benefits. It lowers weight and complexity by limiting anything above the base to a single axis, increasing portability. The Positron 3D Printer, for example, can be assembled in just 60 seconds and fits inside an empty filament box. Additionally, printing orientation has implications for 3D printing in zero gravity, where it has potential applications in space. Overall, while printing orientation may not be a major concern on Earth, exploring unconventional orientations can spark creativity and innovation in the 3D printing community.

| Reprap User Groups | Portuguese RUG | RepLab Working Group | Kartik M. Gada Humanitarian Innovation Prize | Forum Information |

|———————–|————————|———————–|———————————————-|——————–|

| Discussions on | Language: Portuguese | Self-replicating Fab | Gada Prize ideas and projects | Powered by Phorum |

| suppliers | Portugal and Brazil | Lab | Formation of teams | Title: Reprap Forum|

| Meetups | Separate forum for | | Entire forum for RepRap research and | RSS count: 324 |

| Keas and extruder | Brazil | | development | Date: Sept 25, 2020|

| heads | Darwin as the first | | Chat and other fun things with RepRaps | Key point: Designer|

| | RepRap | | | and engineer |

| | RepRaps made from | | | participation |

| | plastic, wood, and | | | |

| | metal | | | |

Benefits of Upside-Down Printing

To understand the benefits of upside-down printing, consider the increased portability and simplified design achieved by limiting anything above the base to a single axis. This orientation offers several advantages:

– Increased Portability:

– By having a low center of gravity and minimal gantry, upside-down printing allows for easy transportation of the printer. It can fit inside an empty filament box, making it highly portable.

– The Positron 3D Printer, for example, can be assembled in just 60 seconds, further enhancing its portability.

– Simplified Design:

– Limiting anything above the base to a single axis reduces weight and complexity. This streamlined design makes the printer more efficient and easier to operate.

– The Positron 3D Printer provides a print volume of 180x180x180mm, allowing for decent-sized prints within its compact design.

– Community Engagement:

– The benefits of upside-down printing have sparked lively discussions among suppliers, meetups, and user groups like the RepRap User Group Nicaragua meetup and RepRap User Group Paraguay gathering. Conversations among enthusiasts often involve topics such as Keas and extruder heads, further advancing the knowledge and development of upside-down printing.

Caleb Kraft’s Passion for Makers

Continuing the discussion from the previous subtopic, let’s delve into Caleb Kraft’s passion for makers. Caleb Kraft is known for his excitement and enthusiasm when it comes to people who make things. He revels in the creativity and ingenuity that makers bring to their projects. Caleb can be contacted via email or found on TikTok, where he shares inspiring stories of makers and their creations. In addition to his online presence, Caleb has written multiple articles on Make.co, a platform that offers various products for makers, including lock pick sets and Arduino starter packs.

When it comes to the Reprap community, Caleb has shown a particular interest in the Reprap User Groups (RUGs). These groups provide a platform for discussions on suppliers, meetups, and topics such as keas and extruder heads. One notable RUG is the Portuguese RUG, which caters to Portuguese-speaking individuals in Portugal and Brazil. The forum has a separate section dedicated to Brazil, highlighting the vibrant RepRap community in the region.

Caleb is also involved in the RepLab Working Group, which focuses on the development of self-replicating Fab Labs. This group explores the possibilities of creating Fab Labs that can reproduce and evolve autonomously, contributing to the growth and accessibility of digital fabrication technologies.

Furthermore, Caleb has shown support for the Kartik M. Gada Humanitarian Innovation Prize. This prize encourages individuals and teams to propose innovative projects that address humanitarian challenges using RepRap technology. The forum dedicated to this prize serves as a hub for discussions, project formation, and sharing of ideas.

It is worth mentioning that the Reprap Forum, where Caleb is an active participant, is powered by Phorum. The forum serves as a platform for designer and engineer participation, fostering a collaborative environment where ideas and knowledge are shared. With its extensive RSS count and a wealth of information, the forum is a valuable resource for those interested in RepRap research and development.

Caleb Kraft’s passion for makers is evident in his dedication to supporting and sharing their stories. Through his involvement in various communities and platforms, Caleb continues to inspire and connect with makers around the world.

Related Articles and Offers

Explore the articles and offers related to 3D printing in the Reprap community. Dive into the vibrant world of 3D printing with these resources:

– Suppliers: Discover a wide range of suppliers offering everything you need for your 3D printing projects. From filament to parts and accessories, these suppliers have you covered.

– Meetups: Connect with fellow 3D printing enthusiasts by attending local meetups. These events provide an opportunity to share knowledge, showcase projects, and network with like-minded individuals.

– Keas and Extruder Heads: Learn about the latest advancements in Keas and extruder heads. These components play a crucial role in the 3D printing process, and staying up to date with the latest innovations can enhance your printing experience.

– RepRap User Group – Nicaragua: Join the RepRap User Group in Nicaragua to engage with a community of passionate 3D printing enthusiasts. Share ideas, seek advice, and collaborate on exciting projects.

– RepRap User Group – Paraguay: Connect with the RepRap User Group in Paraguay to explore the world of 3D printing. Engage in discussions, attend workshops, and stay updated on the latest trends and technologies.

These resources provide valuable insights, opportunities for collaboration, and access to a supportive community of 3D printing enthusiasts. Whether you are a beginner or an experienced maker, these articles and offers will help you take your 3D printing journey to the next level.

Experimenting With 3D Printing Orientation

In the realm of 3D printing, one intriguing area of exploration is the orientation of the printing process. Many experienced 3D printer users have experimented with printing upside down or in unconventional orientations. Angus from Makers Muse conducted an experiment using the UP Plus 2 3D printer to test different orientations, including upside down, right-side up, and sideways. The results showed that the orientation had little impact on the quality of the prints. When printing upside down, a larger object showed some roughness on the bottom, but overall, the quality was not significantly affected. Sideways printing resulted in slightly more variation in print quality, with one side showing more droop compared to the others. These findings suggest that 3D printing in alternate orientations is possible and can be explored further.

While there may be limited practical applications on Earth, the adaptability of 3D printing technology can be harnessed in space, where zero gravity printing has already been developed. This experimentation encourages others to explore unconventional printing directions, sparking creativity and innovation within the 3D printing community.

Results of Upside-Down and Sideways Printing

During the experiment with the UP Plus 2 3D printer, Angus tested different orientations, including upside down and sideways, to observe the effects on print quality. Here are the results:

– Upside Down Printing:

– Angus printed a smaller sphere and a larger size object upside down.

– The smaller sphere did not yield any exciting results or differences.

– The larger object showed roughness on the bottom but looked good overall.

– Upside down printing had very little difference compared to normal orientation.

– The quality of the prints was not significantly affected.

– Sideways Printing:

– Angus experimented with printing sideways to observe the effects of gravity.

– A larger object on a fast-draft setting was used for the sideways test.

– One side of the print showed more droop compared to the others.

– Overall, there was slightly more variation in printing sideways.

– The orientation had minimal impact on the print quality.

These results suggest that printing orientation, whether upside down or sideways, has little effect on print quality. However, it is important to note that these findings were specific to the UP Plus 2 3D printer. Further research may be needed to explore the effects of alternative orientations on different printer models. Nevertheless, these findings have implications for 3D printing in zero gravity applications, where alternative orientations may be necessary.

Implications for 3D Printing in Zero Gravity

3D Printing in zero gravity offers unique opportunities for innovation and exploration. In the context of space, 3D printing can contribute to maintenance tasks and promote sustainability. The adaptability of 3D printing technology allows for printing in unconventional directions, sparking creativity and innovation. While there may be limited need for upside-down or sideways 3D printing on Earth, it is still possible to print in alternate orientations if required. The experiment with printing orientation highlights the potential applications of 3D printing in zero gravity environments, where traditional manufacturing methods may not be feasible. By utilizing 3D printing in space, astronauts can create tools, spare parts, and other necessary objects on-demand, reducing the need for resupply missions and increasing mission autonomy.

Furthermore, 3D printing in zero gravity opens up possibilities for designing and manufacturing objects in ways that were previously unexplored, fostering creativity and pushing the boundaries of what is possible. Overall, 3D printing in zero gravity offers exciting prospects for maintenance, sustainability, and pushing the limits of creativity and innovation.

Exploring Unconventional 3D Printing Possibilities

You can explore unconventional possibilities in 3D printing by considering different orientations. Here are some ideas to paint a picture of what is possible:

– Reprap User Groups:

– Join Reprap User Groups to connect with like-minded individuals and discuss suppliers, meetups, and the latest advancements in 3D printing.

– Explore the RepRap User Group in Nicaragua and Paraguay to engage in discussions specific to those regions.

– Portuguese RUG:

– Dive into the Portuguese RUG, where discussions are conducted in Portuguese, catering to the 3D printing communities in Portugal and Brazil.

– Discover a separate forum dedicated to Brazil, fostering a vibrant community of makers.

– RepLab Working Group:

– Learn about the RepLab Working Group, a community focused on the development of self-replicating Fab Labs.

– Engage in discussions on RepRap research and development, and explore innovative ideas to push the boundaries of 3D printing.

– Kartik M. Gada Humanitarian Innovation Prize:

– Discover the Kartik M. Gada Humanitarian Innovation Prize and explore ideas and projects that aim to make a positive impact on society.

– Form teams to collaborate on innovative solutions and contribute to the RepRap research and development community.

– Forum Information:

– Get involved in the Reprap Forum, powered by Phorum, where designers and engineers actively participate in discussions.

– Stay updated with the latest RSS feeds and key points, and be part of a community that fosters knowledge sharing and collaboration.

Summary of the Experiment and Future Possibilities

To summarize the experiment and explore future possibilities, let’s delve into the results and implications of exploring unconventional 3D printing orientations. The experiment conducted by Angus from Makers Muse using the UP Plus 2 3D printer tested different printing orientations, including upside down and sideways. The results showed that the orientation had little impact on the quality of the prints. When printing upside down, a larger object exhibited roughness on the bottom, but overall, the quality was not significantly affected. Printing sideways resulted in slightly more variation in print quality, with one side of the print showing more droop compared to the others.

These findings suggest that while printing in alternate orientations may not be practical for everyday use on Earth, it highlights the adaptability of 3D printing technology. Looking ahead, possibilities for unconventional 3D printing orientations could lead to new innovations and creative applications. Additionally, it’s worth noting that the Reprap User Groups, Portuguese RUG, RepLab Working Group, Kartik M. Gada Humanitarian Innovation Prize, and Forum Information are valuable resources for further exploration and collaboration within the 3D printing community.