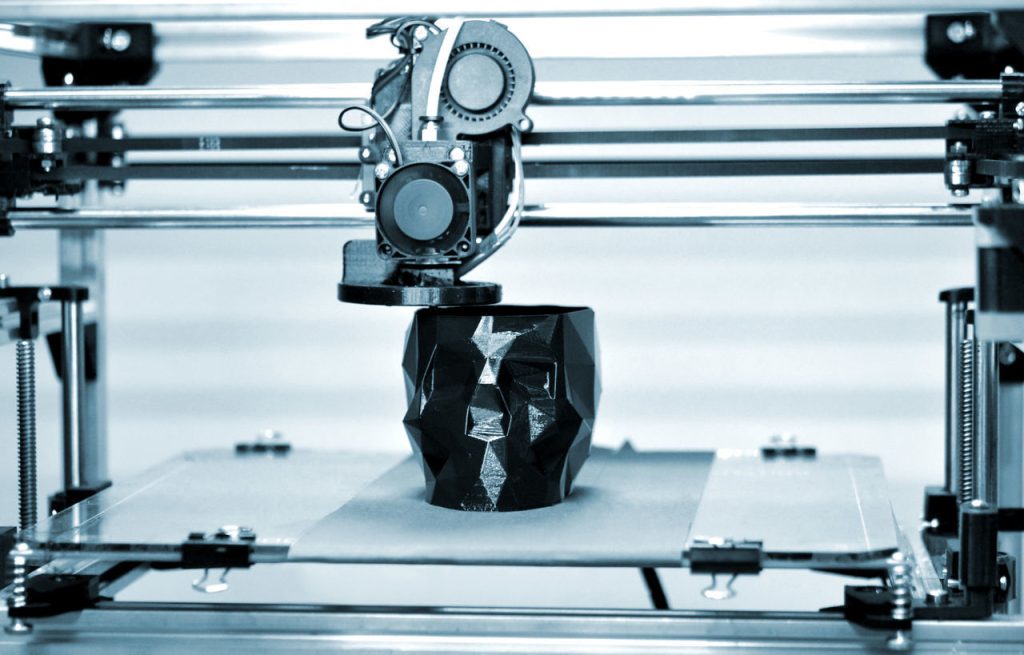

Are you curious about how much a 3D print really costs?

In this article, we’ll explore the factors that influence the pricing of 3D printing services and compare the costs of buying a 3D printer versus hiring a service.

We’ll delve into the various expenses, such as materials, peripherals, maintenance, and energy, to give you a comprehensive understanding of the overall cost.

So, if you’re ready to uncover the truth behind the price tag, let’s get started!

Factors Affecting 3D Printing Service Price

The cost of 3D printing services can vary depending on factors such as the quantity and complexity of the print, as well as any minimum order amounts that may apply. Labor costs and minimum order amounts are factors that affect pricing. Labor is involved in the 3D printing process, even in automated services. Some 3D printing services may require a minimum order amount, such as $90 on platforms like 3DHubs. Ordering multiple quantities can help reduce the overall cost, as economies of scale come into play. It’s important to consider these factors when choosing a 3D printing service, as they can impact the final price of your prints.

Price Comparison of 3D Printing Services

When comparing 3D printing services, you’ll find that prices can vary significantly depending on the provider. Factors affecting pricing, such as the complexity of the print and the quantity ordered, can contribute to price variations.

In a service quality comparison, it’s important to consider the reputation and capabilities of the provider. For example, some providers may offer additional services like support removal and polishing, which can affect the overall cost.

Price comparison of 3D printing services reveals that different providers offer different prices for the same model. Therefore, it’s crucial to research and compare prices before choosing a service.

Reasons for Expensive 3D Printing Services

To understand why 3D printing services can be expensive, you might consider factors such as labor, post-processing, and overhead expenses.

Factors contributing to the high cost include the labor involved in the 3D printing process, as well as the additional time and effort required for post-processing tasks like support removal and polishing.

Overhead expenses, such as the cost of maintaining and operating industrial 3D printers, also contribute to the overall price. These printers can be quite expensive, with prices starting at least $100,000.

In order to cover these expenses and make a profit, 3D printing services add a margin to their prices. While buying a 3D printer may be a more cost-effective option for hobbyists, hiring a service offers access to large-scale printers and advanced capabilities that may not be feasible otherwise.

Comparison Between Buying a 3D Printer and Hiring a Service

If you’re considering whether to buy a 3D printer or hire a service, it’s important to weigh the long-term investment and access to advanced equipment.

Buying a 3D printer can be a better long-term investment for cost-conscious hobbyists. You have the freedom to use the printer whenever you want, without any additional costs per print.

However, if you value your time and need access to advanced technology, hiring a 3D printing service might be a more suitable option. These services offer large-scale printers and advanced capabilities that may not be affordable or practical for individual buyers.

Ultimately, it depends on your specific needs and budget. Consider the long-term costs and benefits of owning a printer versus the convenience and access to advanced equipment provided by a 3D printing service.

Summary of 3D Printing Service Costs

The price of 3D printing services can vary significantly depending on project scale, complexity, and additional variables. Factors affecting pricing include the quantity and complexity of the print, labor involved in the process, and minimum order amounts.

A price comparison analysis reveals that different 3D printing services offer varying prices for the same model, with PrintAWorld being the most affordable option. Factors contributing to the high cost of 3D printing services include labor, post-processing, overhead expenses, and the cost of industrial 3D printers.

However, buying a 3D printer may be a more cost-effective option for hobbyists in the long run. Hiring a service is suitable for those who value their time and need access to advanced equipment.

Overall, the cost of 3D printing services can range from $30 to $15,000, depending on various factors.

3D Printer Price and Types

Standard FDM filament 3D printers, like the Ender 3, can be purchased for around $200.

There are different types of 3D printers available in the market, each with its own price range. FFF printers, which are commonly used for home and hobbyist purposes, can range from a few hundred dollars to $2,000 to $6,000 for higher-performance desktop models.

Desktop SLA printers, on the other hand, start at around $2,000 to $3,000.

If you’re looking for a more professional-grade printer, SLS printers typically cost $10,000 or more. However, keep in mind that larger-scale industrial machines can be significantly more expensive.

When comparing the different types of 3D printers, it’s important to consider your budget and the specific requirements of your projects.

Peripherals and Accessories

Post-processing peripherals are essential for SLA and SLS printers. These peripherals and accessories are essential tools that enhance the overall 3D printing process. They offer upgrades and options for users to improve the quality and efficiency of their prints.

Some examples of post-processing equipment include resin washers, curing chambers, and support removal tools. These peripherals not only help in cleaning and finishing the printed objects but also ensure that they have the desired strength and appearance.

Upgrades and options for these peripherals are available in the market to cater to the specific needs of different users. Investing in these essential tools is crucial for achieving optimal results and maximizing the capabilities of SLA and SLS printers.

Maintenance and Service

Regular maintenance and service for 3D printers involves replacing consumable parts over time. It’s important to consider the cost of repairs when owning a 3D printer. Depending on the brand and model, the cost of repairs can vary.

Some printers offer extended warranty options or annual service plans, which can help cover the cost of repairs. It’s worth checking the support included by the seller, such as installation and maintenance, to ensure you’re getting the best value for your investment.

Additionally, having a warranty in place can provide peace of mind and save you from unexpected expenses. So, when purchasing a 3D printer, be sure to consider the warranty options available to protect yourself from potential repair costs.

Energy Costs

To estimate the electricity expenses of running an Ultimaker 3D printer, you can refer to the power consumption specifications and your usage.

Calculating energy costs is essential to managing your budget effectively.

To reduce energy consumption, consider investing in energy-efficient printers. These printers are designed to use less power while maintaining high-quality prints. By choosing an energy-efficient printer, you can save money on your electricity bills in the long run.

Additionally, it is important to be mindful of your usage habits. Turning off the printer when not in use and optimizing print settings can further minimize energy consumption.

Material Costs

When purchasing materials for your 3D printer, be mindful of the different types available and their corresponding prices.

There are various 3D printing material options to choose from, such as filament for FDM printers and resin for SLA printers. Each material has its own characteristics and suitability for different projects.

To choose the right material for your project, consider factors like strength, flexibility, and surface finish. Additionally, consider the cost of the materials.

Filament prices range from $20 to $50 per kilogram, while resin prices range from $35 to $65 per kilogram.

To reduce material costs, you can optimize your design to minimize the amount of material needed, use infill settings wisely, and consider purchasing materials in bulk to take advantage of discounts.

Cost of 3D Printers

The prices for 3D printers have significantly decreased over time, making them more affordable for average users.

When evaluating 3D printer options, it’s important to consider the cost vs. performance. You want to find a printer that offers a good balance between price and quality.

Look for deals and discounts to buy affordable 3D printers. Online marketplaces like Amazon and eBay often have competitive prices.

Additionally, consider the hidden costs of owning a 3D printer. Maintenance and service costs, energy costs, and material costs can add up over time. Factor these expenses into your budget to get a clear understanding of the total cost of ownership.

Cost of Filament Materials

Now that you understand the cost of 3D printers, let’s dive into the cost of filament materials.

When it comes to filament, there are various options available, each with its own pros and cons. The cost of filament materials can vary depending on the type and brand you choose.

Popular filament types like PLA, ABS, PETG, TPU, ASA, and Nylon range in price from $20 to $50 per kilogram. Hatchbox PLA, for example, costs around $25 per kilogram, while Hatchbox ABS is priced at approximately $22 per kilogram. Overture PETG, on the other hand, is around $21 for 1 kilogram.

It’s important to consider the specific requirements of your project and choose the filament material accordingly.

Cost of Resin Materials

Resin materials, such as Elegoo Rapid Resin and Anycubic UV-Curing Resin, start at around $35 per kilogram and can go up in price for premium options with enhanced characteristics.

When considering the cost of resin materials for your 3D printing projects, it’s important to explore different resin material options and their pricing.

While the starting price for resin materials is relatively affordable, there are also premium resins available at higher prices that offer advanced features.

It’s essential to choose the resin material that best suits your specific project requirements and budget.